How Can You Integrate Lights Inside Latex Balloons Safely for a Magical Glow?

Struggling to make your events truly shine? Standard decorations can feel flat, and creating a magical, glowing atmosphere seems complex and risky. But it is simpler than you might imagine.

To create a safe and magical glow, use small, battery-operated LED lights1. Insert the light into the latex balloon before you inflate it. For the best effect, choose clear or light-colored balloons. This method ensures the light is secure, bright, and completely safe for any occasion.

You now have the basic method down. But for a professional buyer, there is much more to consider. When you are responsible for sourcing thousands of units2 for a major retailer, you need to think about manufacturing types, safety compliance3, and supplier reliability4. Let's explore the details that matter for large-scale procurement. I want to help you make the best choice for your business.

What are the different types of LED lights used for bulk balloon manufacturing?

Choosing the wrong LED type for a large order can feel overwhelming. A poor decision can lead to customer complaints or unexpected costs. Understanding the main options helps you select wisely.

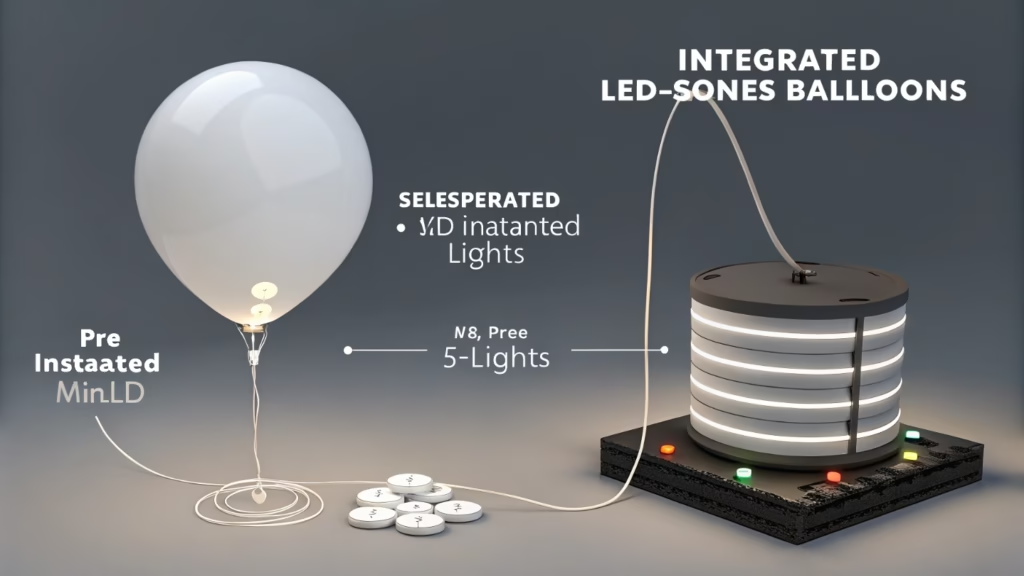

For bulk manufacturing, there are two primary options: integrated LED balloons5, where the light is pre-installed at the factory, and separate mini LED units6, which are packaged separately for the customer to insert. Your choice depends on your priorities for convenience versus cost and flexibility.

When I speak with procurement managers like Sarah at GlobalMart, the conversation always turns to operational efficiency and final product quality. The type of LED you choose directly impacts both. Let's break down the two main categories for bulk orders.

1. Integrated LED Balloons

These are balloons that come with the LED light and battery already secured inside. The light is typically activated by pulling a small tab before inflation. From a manufacturing standpoint, this requires precise assembly to ensure the light is positioned correctly and the activation tab works flawlessly. We invest heavily in quality control for these products to prevent duds.

2. Separate Mini LED Units

This option involves supplying standard latex balloons alongside small, individual LED lights. These lights are usually small spheres or capsules that the end-user drops into the balloon. While this lowers the manufacturing complexity of the balloon itself, it shifts the assembly to the customer.

As a procurement professional, your decision depends on balancing factors like unit cost, user experience, and supply chain complexity. Here is a simple comparison:

| Feature | Integrated LED Balloons | Separate Mini LED Units |

|---|---|---|

| Assembly | None for the end-user | User must insert the light |

| Unit Cost | Generally higher | Generally lower |

| User Experience | Very convenient, "grab and go" | Requires an extra step |

| Best For | Retail party packs, event planners | DIY kits, cost-sensitive markets |

For a large retailer, integrated balloons often provide a better, more consistent customer experience, reducing the chances of user error and complaints.

What safety certifications are required for importing LED-integrated latex balloons?

Importing products without the right paperwork is a massive risk. Your shipment could be stopped at the border, leading to costly delays or even total loss of inventory. Focusing on key certifications ahead of time prevents these headaches.

For importing to Europe and North America, you must have toy safety and electronics compliance. Key certifications include CE (EN71)7 for Europe and ASTM F9638 for the USA. For the electronics, look for RoHS compliance9 for hazardous substances and FCC for electronic interference in the US.

In my 10 years in this industry, I've seen how critical compliance is, especially for large retail partners. A missing certificate is not a small oversight; it’s a deal-breaker that can damage a brand's reputation. At AIHUA BALLOON, we treat certifications as a core part of our product promise.

When sourcing LED-integrated balloons, you are dealing with two product categories at once: a toy and an electronic device. This means you need to satisfy regulations for both.

Toy Safety Standards

These standards ensure the product is safe for children, covering physical and chemical hazards.

- CE & EN71 (Europe): The CE mark shows a product meets EU safety, health, and environmental requirements. EN71 is the specific European standard for toy safety, which is essential for any balloon product.

- ASTM F963 (USA): This is the mandatory toy safety standard in the United States. It covers things like small parts, sharp edges, and material safety.

Electronics Compliance

These standards relate to the LED light and battery.

- RoHS (Europe): This stands for Restriction of Hazardous Substances. It certifies that the electronic components do not contain specific hazardous materials like lead or mercury.

- FCC (USA): The Federal Communications Commission requires this certification to ensure the electronic device does not produce harmful electromagnetic interference.

As a buyer, you should always request a full documentation package from your supplier. Here's a checklist to use:

| Certification | Region | What It Covers | Why It's Important |

|---|---|---|---|

| CE (EN71) | Europe | General toy safety | Required for market access in the EU |

| ASTM F963 | USA | Toy safety, small parts | Mandatory for all toys sold in the US |

| RoHS | Europe | Hazardous materials in electronics | Protects consumer health and environment |

| FCC | USA | Electromagnetic interference | Prevents interference with other devices |

Working with a Sedex or ISO9001-certified factory adds another layer of assurance. It shows the manufacturer is committed to ethical practices and consistent quality management, which supports overall product safety.

How does battery life and LED brightness vary across different wholesale suppliers?

You find two suppliers offering LED balloons at very different prices. The cheaper option seems tempting, but you worry about performance issues. This variation often comes down to the hidden components: the battery and LED.

Battery life and LED brightness10 vary significantly based on the quality of the components used. Premium suppliers use higher-capacity batteries for longer glow times (8-24 hours) and brighter LEDs. Lower-cost options may only last a few hours and appear dim, disappointing customers.

This is a topic I discuss often because it directly affects the customer's "magical" experience. A balloon that dies halfway through a party is a failure. As a manufacturer, we know that the small details inside the balloon make all the difference. The quality of the LED and the battery are non-negotiable for us.

Let's look at what determines performance.

Key Factors Influencing Performance

- Battery Type and Capacity: Most balloon lights use small button cell batteries (like LR41 or CR927). The capacity, measured in milliampere-hours (mAh), determines how long the light will last. A higher-quality battery costs more but provides a much longer and more reliable glow.

- LED Quality: Not all LEDs are created equal. The brightness, measured in lumens, and energy efficiency can vary. A high-quality LED will produce a brilliant light without draining the battery too quickly. Low-quality LEDs can be dim from the start or fade fast.

- Circuitry: The simple circuit inside the light unit also plays a role. A well-designed circuit optimizes power usage, extending the functional life of the balloon.

Here's what you can typically expect from different quality tiers:

| Quality Tier | Typical Battery Life | Brightness Level | Common Use Case |

|---|---|---|---|

| Premium | 15-24+ hours | Bright & Consistent | Weddings, corporate events, high-end retail |

| Standard | 8-15 hours | Good, may dim over time | General party supplies, retail packs |

| Economy | 2-8 hours | Noticeably dimmer | Bulk giveaways, single-evening events |

When evaluating suppliers, don't just ask for a price. Ask for a technical data sheet. Request samples and test them yourself. Time how long they stay bright. At AIHUA BALLOON, we provide full performance reports because we want our partners to be confident in the product they're selling. The lowest price is rarely the best value.

Can custom branding be added to light-up balloons for large volume orders?

You want your company's brand to be part of a magical event experience. But you're not sure if it's possible to print a logo on a balloon that also needs to light up effectively. This concern can limit your marketing opportunities.

Yes, custom branding11 can absolutely be added to light-up balloons for large volume orders. High-quality screen printing12 allows logos or messages to be printed on the latex. For the best visibility, use a bold, one-color design and place it on a light-colored or translucent balloon.

Branded merchandise is a powerful tool, and LED balloons offer a unique way to capture attention. I've worked with many corporate clients to create custom-printed LED balloons for product launches and promotional events. The key is to balance the branding with the balloon's primary feature: the light.

The printing process itself is straightforward. We use the same high-quality screen printing method for LED balloons as we do for our standard latex balloons. However, there are a few design considerations to maximize the effect.

Best Practices for Branding LED Balloons

- High-Contrast Colors: A dark ink on a light-colored balloon works best. For example, a black or dark blue logo on a white, yellow, or pink LED balloon will be very clear when lit. Printing a light color on a dark balloon is possible, but the internal glow may wash it out.

- Simple, Bold Designs: Intricate, multi-color logos can become hard to read when the balloon is glowing. The light source creates a slight diffusion effect. A simple, bold logo or a clear wordmark will have the most impact.

- Print Placement: We typically recommend printing on one side of the balloon. This ensures the logo is the focal point, while the rest of the balloon provides a beautiful, even glow.

Here’s a table outlining the possibilities for a procurement manager:

| Feature | Description | Recommendation for Impact |

|---|---|---|

| Printing Method | Silk-screen printing | Ensures durable and opaque ink coverage. |

| Ink Color | 1-2 solid colors | Stick to your primary brand colors, using dark ink for best results. |

| Balloon Color | White, Pastels, Translucent | These colors act as the best diffusers for the internal LED light. |

| Minimum Order | Varies by supplier | Typically starts at 5,000-10,000 units for custom prints. |

When you place a large custom order, always ask for a pre-production sample13. This allows you to see exactly how your branding looks on an illuminated balloon before committing to the full run. It's a simple step that guarantees you'll be happy with the final product.

Conclusion

Integrating lights into latex balloons is straightforward and safe with the right components. For professionals, success depends on understanding LED types, safety compliance3, performance metrics, and customization options to ensure quality.

-

Explore how battery-operated LED lights can enhance your event's atmosphere and safety. ↩

-

Get tips on sourcing large quantities of event supplies efficiently. ↩

-

Understand the importance of safety compliance in LED product manufacturing. ↩ ↩

-

Learn how to evaluate suppliers to ensure quality and reliability. ↩

-

Discover the convenience and benefits of using integrated LED balloons for events. ↩

-

Find out how separate mini LED units can offer flexibility for DIY projects. ↩

-

Discover the significance of CE (EN71) certification for toy safety in Europe. ↩

-

Learn about ASTM F963 and its role in ensuring toy safety in the USA. ↩

-

Understand the importance of RoHS compliance in electronic products. ↩

-

Learn about the factors that determine LED brightness in balloon lighting. ↩

-

Discover how to effectively brand light-up balloons for your events. ↩

-

Understand the screen printing process for customizing balloons. ↩

-

Find out how pre-production samples can ensure satisfaction with your order. ↩