How Do You Create a Perfect Sphere Shape When Inflating Round Latex Balloons?

Tired of your balloon decorations looking pear-shaped instead of perfectly round? This common problem can ruin a professional look. I will show you the simple technique to fix it.

To create a perfect sphere1, you must first overinflate the latex balloon2 slightly. Then, gently release some air while using your hands to press and shape the balloon. This stretching process reshapes the latex from its natural pear form into a smooth, perfectly round sphere for professional results.

Getting the shape right is a great start. But achieving this look consistently depends on more than just technique. Many factors go into that perfect, bubbly appearance. Let's explore what really makes a difference, starting with the material of the balloon itself.

Does the quality of latex affect the final spherical shape?

You followed all the right steps, but some balloons just will not shape correctly. This wastes time and causes frustration. The quality of the latex is often the hidden reason.

Yes, high-quality latex3 is crucial for a perfect sphere. Superior latex has better elasticity, so it stretches evenly without creating weak spots. This makes it much easier to shape and reduces the risk of popping during the essential overinflation step.

As someone who has spent years in balloon manufacturing, I can tell you that not all latex is created equal. The final shape of a balloon is directly tied to the raw material and our production process. High-quality latex, sourced from premium rubber trees, has a more uniform molecular structure4. This allows it to expand in all directions at the same rate.

Cheaper balloons often use lower-grade latex with impurities or inconsistent thickness. When you try to overinflate these, thin spots can develop, leading to a distorted shape or, even worse, a sudden pop. At AIHUA, we ensure our latex mixture and dipping process create a balloon wall of consistent thickness. This is key for reliable stretching. Think of it like the difference between a cheap rubber band and a high-performance one. One stretches predictably, while the other might snap unexpectedly.

Key Differences in Latex Quality

| Feature | High-Quality Latex (like ours) | Low-Quality Latex |

|---|---|---|

| Elasticity | Stretches evenly in all directions | Stretches unevenly, creates weak spots |

| Durability | Withstands overinflation for shaping | Prone to popping under pressure |

| Shape Memory | Holds a round shape well after shaping | Tends to revert to a pear or oval shape |

| Consistency | Uniform thickness and color | Inconsistent thickness, may have blemishes |

What inflation techniques prevent the common 'pear shape'?

Your balloon garlands can look amateurish with those pointy, pear-shaped balloons. This undermines the beautiful, professional finish you want to achieve. A specific inflation method can solve this problem entirely.

To avoid a 'pear shape5,' you need to overinflate the balloon past your target size. Next, release air slowly while pressing and massaging it into a round form. This 'burping' technique stretches the latex evenly and is the secret to a perfect sphere.

The natural shape of a latex balloon when first inflated is a teardrop or pear. This is because the area near the neck is thicker and less flexible. The trick is to force the latex to stretch beyond its initial memory. Here at AIHUA BALLOON, we use this exact method when testing our products for professional decorators.

Let me break down the steps for you.

Step 1: Overinflate the Balloon

First, inflate the balloon until it is quite large and firm, going beyond the final size you want. For example, if you want a 9-inch round balloon from an 11-inch product, inflate it to the full 11 inches first. This is the most important step because it stretches the latex, especially at the less-pliable top of the balloon.

Step 2: Release Air and Shape

While pinching the neck to control the airflow, let some air out. As you do this, use your other hand or your body to press down on the top of the balloon. You can press it against a flat table or even your chest. This pressure helps redistribute the remaining air and encourages the balloon to form a sphere. You are actively reshaping the stretched latex.

Step 3: Check for Roundness

Continue to release air and press until you have a perfectly round shape, free of any points or ovals. The final balloon will be smaller and softer than its maximum size, but it will have that beautiful, bubble-like appearance that makes garlands and bouquets look so high-end.

What should buyers look for in a supplier of perfectly round latex balloons?

You need balloons that consistently create a perfect sphere. But choosing the wrong supplier can lead to inconsistent products and unreliable delivery. This directly impacts your business and your clients' satisfaction.

Look for a supplier with a long history of quality manufacturing and international certifications like Sedex and ISO90016. A reliable supplier provides comprehensive quality reports, communicates clearly, and can prove their products meet global safety standards like EN71.

As a procurement manager, your goal is to find a partner, not just a seller. After more than 37 years in this industry, I know what separates a great supplier from an average one. It comes down to trust, which is built on proof of quality and reliability.

First, check their experience and certifications. A long manufacturing history, like ours at AIHUA, shows stability and expertise. Certifications like ISO9001 demonstrate a commitment to a documented quality management system. A Sedex report shows the supplier is serious about ethical and responsible business practices. These are not just papers; they are proof of a professional operation.

Second, ask for detailed product specifications and quality reports. A good supplier will be transparent about their latex sourcing7, balloon weight8, and color consistency9. We provide batch testing reports10 to our partners, showing results for durability and safety compliance with standards like EN71. This data gives you the confidence that every balloon will perform as expected.

Finally, evaluate their communication and service. A strong supplier works with you to understand your needs, from custom colors to specific packaging. They should be responsive, professional, and able to manage complex logistics to ensure on-time delivery.

How can you ensure consistent sizing and shape for bulk balloon orders?

You place a large order expecting uniform balloons, but the delivery contains different sizes and shapes. This inconsistency creates problems for large-scale decorations and retail packaging. It reflects poorly on your brand.

To ensure consistency, partner with a manufacturer that uses precise, automated dipping11 and quality control systems. Provide a detailed specification sheet with your order, including Pantone colors and size tolerances. Also, request pre-production samples12 to approve before the full order is made.

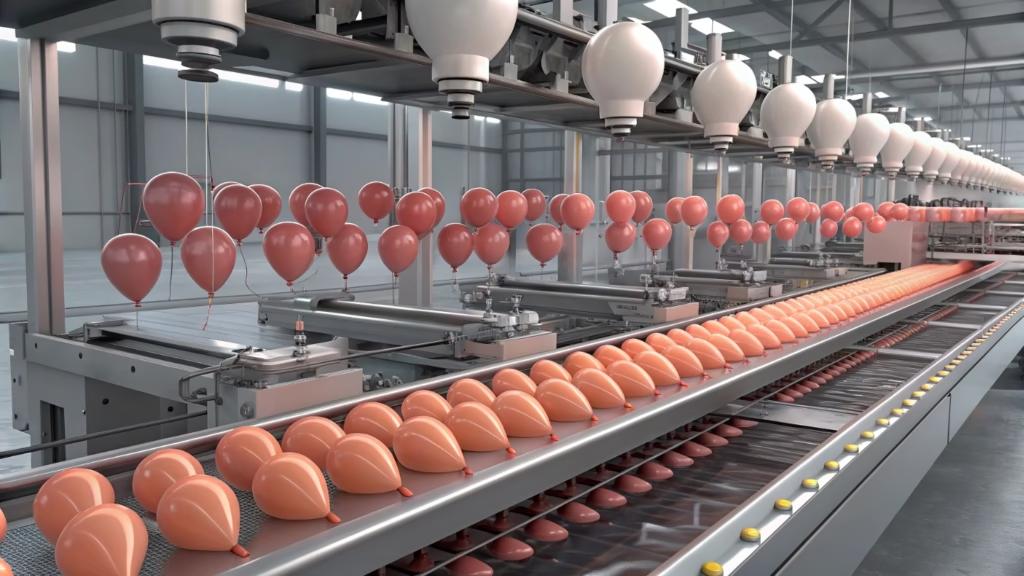

Consistency in a bulk order is not an accident. It is the result of a rigorous and controlled manufacturing process. When I oversee our production lines, I focus on three key areas to guarantee every balloon meets our clients' standards.

First is the technology. Modern, automated dipping11 lines are essential. They ensure that every balloon form is dipped into the latex for the exact same amount of time and at the same depth. This precision is what creates a consistent wall thickness, which is critical for both uniform shape and size upon inflation. Hand-dipping or older machinery simply cannot match this level of accuracy for large volumes.

Second is clear specification. As a buyer, you should provide a technical sheet with your requirements. This includes the balloon's flat size, the desired inflated size, weight in grams, and specific Pantone codes for color matching. The more detailed your request, the better a quality manufacturer can meet it. We use these sheets as a blueprint for production.

Quality Control Checklist for Bulk Orders

| Control Point | What to Ask Your Supplier | Why It Matters |

|---|---|---|

| Pre-Production | Do you provide samples for approval? | Confirms color, size, and quality before mass production. |

| During Production | What are your in-line quality checks? | Catches deviations in real-time, reducing defects. |

| Post-Production | Can you provide a final QC report? | Verifies that the completed batch meets all specifications. |

Finally, always request pre-production samples. This allows you to physically test and approve the balloons yourself. Once you approve the sample, the manufacturer has a clear standard to match for the entire production run. This simple step eliminates surprises and ensures the final delivery is exactly what you expect.

Conclusion

Achieving a perfect sphere depends on quality latex and the right inflation technique. By partnering with a reliable supplier, you can ensure every balloon performs perfectly for consistently beautiful results.

-

Discover expert techniques to achieve a flawless spherical shape for your balloon decorations. ↩

-

Learn why overinflating is crucial for achieving the perfect balloon shape. ↩

-

Explore the advantages of high-quality latex in balloon decoration and durability. ↩

-

Understand the science behind latex molecular structure and its impact on balloons. ↩

-

Get tips on preventing pear shapes in balloons for a polished look. ↩

-

Find out how ISO9001 certification ensures quality in balloon manufacturing. ↩

-

Learn about the importance of sourcing quality latex for balloon production. ↩

-

Understand the impact of balloon weight on decoration and durability. ↩

-

Explore why color consistency matters for professional balloon displays. ↩

-

Find out how batch testing reports ensure balloon safety and quality. ↩

-

Discover how automation enhances the quality and consistency of balloon production. ↩ ↩

-

Learn the significance of pre-production samples in ensuring quality. ↩