Latex vs Foil: What Are the Key Differences in Materials and Manufacturing Processes?

Choosing between latex and foil balloons affects your inventory costs and customer satisfaction. Making the wrong choice can lead to complaints about float times1 or sustainability issues2.

Latex balloons are made from natural rubber3 and are cost-effective and biodegradable4, making them ideal for bulk events. Foil balloons use metalized nylon for superior durability and helium retention5, lasting for weeks. Your choice depends on whether you prioritize eco-friendliness6 or long-lasting display capabilities.

I have seen many buyers confused by the technical specs of these two types. Let me break down the science and production methods7 to help you make better purchasing decisions.

What are the key material differences between latex and foil balloons?

You need to understand the raw materials to explain quality differences to your customers. Ignoring material composition can lead to safety compliance issues in different markets.

The main difference lies in the source of the material. Latex balloons come from natural sap harvested from Hevea brasiliensis trees, offering elasticity. Foil balloons consist of non-porous nylon sheets coated with metallic materials. This fundamental difference dictates their texture, stretch, and overall performance in retail environments8.

I have spent over a decade in this industry, and I always tell my clients to start with the raw material. At AIHUA BALLOON, we source our latex directly from rubber trees. This is an organic material. It is a polymer that stretches. When you look at a latex balloon under a microscope, it looks like a mesh of strands. This structure gives it the "bounce" that party planners love.

On the other hand, foil balloons are not actually made of foil. We call them Mylar, which is a brand name for a specific type of plastic called BoPET (Biaxially-oriented polyethylene terephthalate). Manufacturers coat this plastic with a very thin layer of aluminum. This is what gives it the shiny, metallic look. It does not stretch like latex. If you over-inflate it, it will pop immediately because the material is rigid.

Here is a simple breakdown of the material properties:

| Feature | Latex Balloons | Foil (Mylar) Balloons |

|---|---|---|

| Primary Component | Natural Rubber Sap | Synthetic Nylon/BoPET |

| Elasticity | High (Stretches significantly) | Zero (Rigid structure) |

| Porosity | Porous (Gas escapes easily) | Non-porous (Traps gas well) |

| Texture | Soft, smooth, matte or shiny | Crinkly, metallic, reflective |

How do manufacturing processes differ for latex versus foil balloons?

Production methods directly impact your defect rates9 and lead times. If you do not know how they are made, you cannot effectively audit your suppliers.

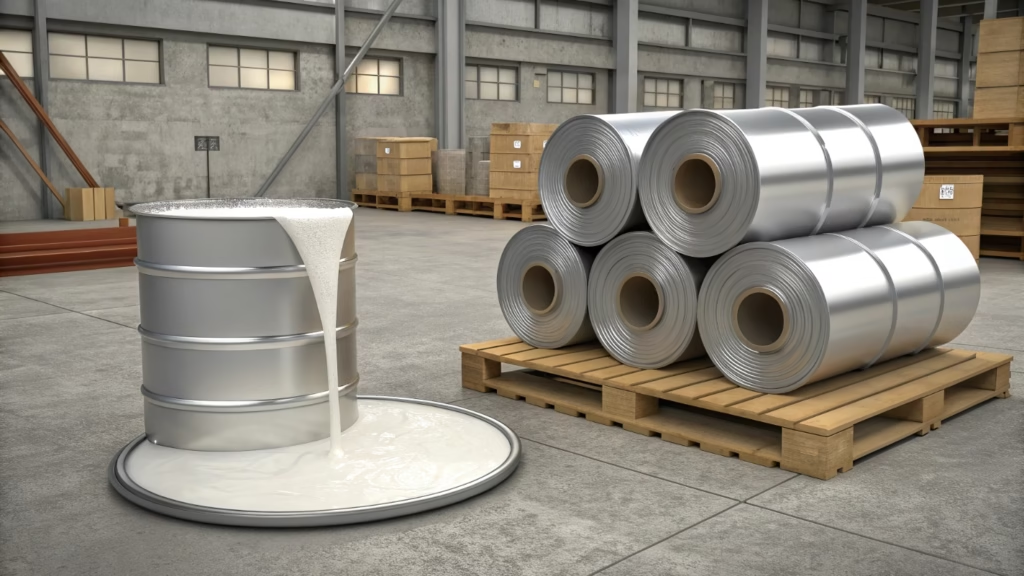

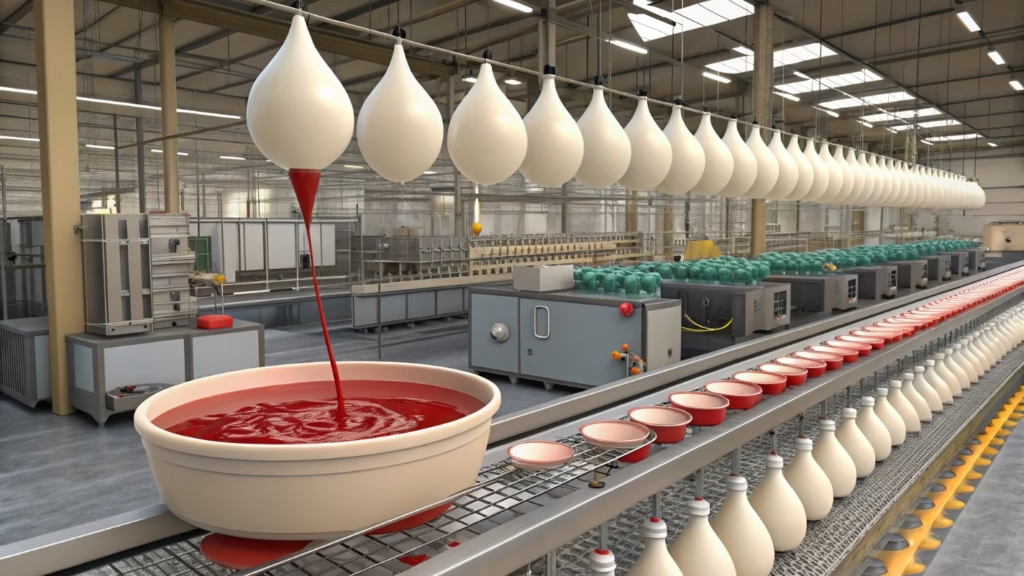

Latex production involves dipping ceramic molds into liquid rubber and curing them in ovens. Foil manufacturing is a printing and heat-sealing process where sheets are welded together. These distinct methods require different quality control10 checkpoints to ensure standard compliance.

The manufacturing process is where the magic happens. For latex balloons, imagine thousands of ceramic hand-shaped molds moving along a conveyor belt. We clean these molds and then dip them into a coagulant. After that, we dip them into the liquid latex mix. The latex sticks to the mold. We then pass them through large ovens to vulcanize the rubber. This baking process makes the rubber strong. Finally, we strip the balloon off the mold. It is a chemical and heat-based process.

Foil balloons are made completely differently. It is more like making a bag of potato chips. We start with large rolls of the plastic film. We print the designs onto the flat sheet first. Then, we put two sheets together. A machine presses down with a hot die in the shape of the balloon (like a star or a dinosaur). This heat seals the edges together. We also insert a self-sealing valve during this step. Then a cutter cuts out the shape.

Key Production Steps

-

Latex Process:

- Acid wash and brushing of formers.

- Dipping in coagulant.

- Dipping in latex tank.

- Oven curing (Vulcanization).

- Stripping and tumbling.

-

Foil Process:

- Extrusion of nylon film.

- Metallization (adding aluminum layer).

- Rotogravure printing.

- Heat sealing and valve insertion.

- Die-cutting.

Which balloon type offers superior durability and helium retention?

Customer complaints often center on balloons deflating too quickly. This hurts your brand reputation and causes retailers to lose trust in your supply.

Foil balloons win this category easily because their non-porous material traps helium for weeks. Latex balloons are porous, allowing gas to escape within 12 to 24 hours. Understanding this helps you manage expectations for event planners11 and retail stores.

When I speak with supply chain managers like Sarah, durability is always a top concern. Helium atoms are very small. They are the second smallest element on the periodic table. Because latex is a natural material, it has microscopic pores. Imagine a net. The helium atoms are smaller than the holes in the net. They slowly escape through the skin of the balloon. This is why a standard latex balloon only floats for about 12 to 24 hours. You can use a gel treatment like Hi-Float to block these pores, but without it, the float time is short.

Foil balloons are different. The metalized nylon creates a nearly perfect barrier. It is like a solid wall compared to the net of the latex balloon. The helium cannot pass through the plastic and aluminum layers easily. A quality foil balloon can stay inflated for two weeks or even a month. Also, foil balloons are physically tougher against sharp objects, but they cannot handle heat. The gas expands in heat and can burst the rigid seams.

Durability Comparison Table

| Factor | Latex Balloon | Foil Balloon |

|---|---|---|

| Float Time (Helium) | 8 - 24 Hours | 3 - 30 Days |

| Outdoor Use | Oxidizes (foggy look) in sun | Retains shine, but heat sensitive |

| Pop Resistance | Popping is loud, pieces scatter | Usually tears at the seam |

| Reusability | Single-use only | Can be deflated and reused |

How do environmental impacts compare between biodegradable latex and mylar foil?

Sustainability is a major pressure point for large retailers like GlobalMart today. Ignoring eco-friendly options can alienate modern consumers and fail corporate responsibility goals.

Latex balloons are biodegradable and break down at the same rate as an oak leaf. Foil balloons are synthetic and non-biodegradable but can be reused multiple times. You must balance disposable eco-friendly options with reusable long-term products in your inventory.

This is a topic I am very passionate about. In the balloon industry, we face a lot of questions about plastic waste. It is important to know the facts. High-quality latex balloons, like the ones we make at AIHUA, are 100% biodegradable. They come from nature, and they go back to nature. If you bury a latex balloon in the ground, bacteria will eat it. It decomposes at roughly the same speed as an oak leaf. However, this depends on the environment. It needs sunlight and soil to break down properly.

Foil balloons are not biodegradable. They are made of synthetic plastics and aluminum. They will sit in a landfill for hundreds of years. This is a big negative for eco-conscious buyers. However, the advantage of foil is reusability12. You can insert a straw into the valve, push the gas out, fold it up, and use it again next year. This creates less immediate waste compared to single-use items.

Recommendations for Buyers

- For Eco-Focused Brands: Prioritize latex balloons. Ensure your supplier has certifications proving the natural origin of the rubber.

- For Premium/Gift Lines: Use foil balloons but educate customers on reuse. Encourage them not to release balloons into the sky, as foil can conduct electricity and harm power lines.

Conclusion

Latex balloons offer a cost-effective, biodegradable solution for bulk decor, while foil balloons provide superior durability and complex designs for premium retail13. As a procurement manager, you should stock a mix of both to meet different customer needs for price, longevity, and sustainability.

-

Understand the factors that influence how long balloons stay inflated. ↩

-

Explore the environmental challenges associated with balloon production and disposal. ↩

-

Find out more about natural rubber, its properties, and its applications in various industries. ↩

-

Learn about the significance of biodegradable products in reducing environmental impact. ↩

-

Understand the science behind helium retention and how it affects balloon performance. ↩

-

Discover strategies for making products more sustainable and appealing to eco-conscious consumers. ↩

-

Gain insights into the manufacturing processes that affect balloon quality and performance. ↩

-

Explore the unique challenges faced by balloons in retail settings and how to address them. ↩

-

Understand how defect rates can impact product quality and customer trust. ↩

-

Learn about the importance of quality control in ensuring product reliability and safety. ↩

-

Discover the key factors that event planners consider when selecting balloons for occasions. ↩

-

Find out how to extend the life of balloons through proper reuse techniques. ↩

-

Discover the latest trends in premium balloon offerings and consumer preferences. ↩