Latex vs Mylar Balloons: How do they impact allergy considerations for customers?

Worried a simple balloon could trigger a customer's allergy? This hidden risk can ruin a celebration. Understanding the material differences is key to ensuring everyone's safety and enjoyment.

For a truly safe celebration, Mylar balloons are the best choice. Latex balloons contain natural proteins that can cause severe allergies. Mylar balloons are made from a hypoallergenic plastic film1, completely eliminating the risk of a latex-related allergic reaction for your customers and ensuring an inclusive event.

As a procurement manager2, you're not just buying a product; you're ensuring the safety and satisfaction of millions of customers. A balloon seems simple, but the material choice has significant implications. I've seen how this choice directly impacts brand reputation and customer trust. That's why I always advise my partners to look beyond the price tag and consider the real-world impact. Let’s break down exactly what makes some balloons a potential risk and how you can protect your customers and your brand.

What specific allergens in latex balloons pose a risk to customers?

You know latex can cause allergies, but what exactly is the trigger? Without knowing the specific cause, it's difficult to assess the real risk or explain it to your team. The danger lies in specific natural proteins.

The primary allergens in latex balloons are natural rubber proteins3. A fine powder, often used in manufacturing, can bind to these proteins. This powder becomes airborne when balloons are handled, leading to allergic reactions even without direct skin contact. This makes inhalation a significant risk.

At AIHUA BALLOON, we take material science seriously because it directly impacts public health. The allergen in question comes from the sap of the Hevea brasiliensis rubber tree. This natural substance contains proteins that, for some people, trigger an immune response. The risk isn't just from touching the balloon. The cornstarch powder used to prevent balloons from sticking together in the package can act as a carrier for these proteins. When a balloon pops or is even just handled, these protein-coated particles can fill the air in a room, leading to respiratory symptoms.

There are two main types of reactions to be aware of:

| Reaction Type | Allergen Source | Onset & Symptoms |

|---|---|---|

| Type I | Natural Rubber Latex Proteins | Immediate. Hives, wheezing, and in severe cases, anaphylaxis. This is the most dangerous reaction. |

| Type IV | Processing Chemicals | Delayed (24-48 hrs). Itchy rash, blisters (contact dermatitis). Less severe but still problematic. |

For a procurement manager like yourself, understanding the airborne risk4 of Type I reactions5 is critical for liability and customer safety.

Are Mylar balloons considered a safe, hypoallergenic alternative for events?

You need a balloon that's guaranteed safe for everyone, especially at large events. Choosing the wrong type could exclude guests or, worse, cause a medical emergency and damage your company's reputation. Mylar balloons offer a reliable, stylish, and completely hypoallergenic solution.

Yes, Mylar balloons are a safe, hypoallergenic alternative. They are made from a nylon sheet coated with a metallic finish. This material contains no natural rubber latex proteins, completely removing the risk of triggering latex allergies and ensuring all guests can celebrate without concern.

Mylar balloons, which we often call foil balloons in the industry, are the definitive choice for an allergy-conscious inventory6. Their construction is fundamentally different from latex. They are crafted from a type of plastic film (biaxially-oriented polyethylene terephthalate, or BoPET) and then coated with a layer of metallic material like aluminum. This composition is entirely synthetic and contains none of the natural proteins found in rubber latex. Therefore, they cannot trigger a Type I latex allergy.

From my experience working with large retailers, the switch to promoting Mylar as the "allergy-safe" option has significant benefits beyond safety.

- Durability: They hold helium for weeks, not hours, leading to higher customer satisfaction and a longer-lasting display.

- Premium Appearance: Their reflective surface and crisp printing capabilities offer a high-end look that commands a better price point.

- Reusable: The self-sealing valves often allow them to be deflated and reused, which is a value-add that customers appreciate.

For your supply chain, this means offering a product that is not only safer but also perceived as higher quality.

How can wholesalers ensure their balloon stock meets safety and allergy standards?

You know the risks, but how do you protect your business? Stocking the wrong product could lead to customer complaints, legal issues, and damage to your brand's credibility. You need a clear strategy to ensure compliance and safety across your entire supply chain.

Wholesalers must partner with certified manufacturers7 who provide comprehensive product documentation. Demand material safety data sheets (MSDS), test reports for allergens, and certifications like Sedex8 and ISO 90019. A clear separation of latex and Mylar products in warehousing is also essential.

As a manufacturer, this is where our partnership becomes crucial. Ensuring your stock is safe begins long before the products reach your warehouse. You need to implement a strict supplier verification process. When I work with a new partner like GlobalMart, I always provide a full compliance package upfront. You should demand this from every supplier.

Here are the key actions to take:

- Request Full Documentation: Don't just take a supplier's word for it. Ask for Material Safety Data Sheets (MSDS)10 that detail the balloon's composition. For latex balloons, request specific test reports that quantify the level of leachable proteins.

- Verify Certifications: Look for suppliers who are audited and certified under global standards. Sedex demonstrates ethical supply chain practices, while ISO 9001 confirms a commitment to quality management. These aren't just logos; they represent a system of accountability.

- Implement Warehouse Protocols: Even with safe products, cross-contamination11 is a risk. Store latex and foil balloons in separate, clearly marked areas. The fine powder from latex products can settle on other inventory if not properly managed.

This rigorous approach protects your customers and builds a defensible position for your business, demonstrating due diligence at every step.

What labeling requirements should importers be aware of regarding latex content?

Importing products brings another layer of complexity. What happens if your packaging doesn't meet the legal requirements for allergy warnings in a specific market? This oversight can lead to recalled products, fines, and a complete halt to sales.

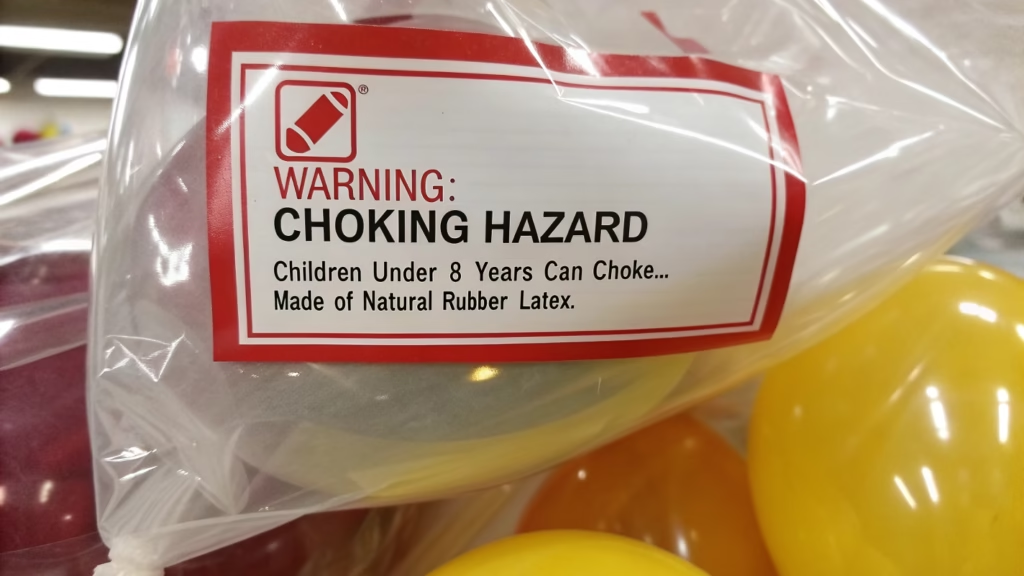

Importers must comply with country-specific regulations. In the U.S., the CPSC12 requires a clear warning label on packaging for latex balloons, stating they can cause choking and pose a risk to children and individuals with latex allergies.

Navigating international regulations is a huge part of my role. Each market has its own nuances, and it is your responsibility as the importer to ensure full compliance. For North America and Europe, the requirements are quite stringent.

In the United States, the Consumer Product Safety Commission (CPSC) mandates specific warning language for any toy or product intended for children that contains latex. The warning must be conspicuous and state something similar to: "WARNING: CHOKING HAZARD—Children under 8 yrs. can choke or suffocate on uninflated or broken balloons. Adult supervision required. Keep uninflated balloons from children. Discard broken balloons at once. Made of natural rubber latex."

While this focuses on choking, the phrase "Made of natural rubber latex" is the key piece for allergy sufferers. For the European market, the CE mark13 is essential, indicating conformity with health, safety, and environmental protection standards. The Toy Safety Directive also requires potential allergens to be declared.

My advice is simple: work with a manufacturer who already serves global markets. At AIHUA BALLOON, we produce packaging variants for each region we ship to, ensuring the correct legal warnings are already in place. This saves you time, reduces risk, and ensures your product can go straight to shelf without compliance delays.

Conclusion

Understanding the differences between latex and Mylar balloons is vital for customer safety. Mylar offers a hypoallergenic solution, while latex requires clear warnings and careful handling for allergy-prone individuals.

-

Understand the materials used in Mylar balloons that make them a safe choice for allergy-sensitive individuals. ↩

-

Explore the critical responsibilities of procurement managers in ensuring product safety and compliance. ↩

-

Discover how natural rubber proteins in latex can trigger severe allergic reactions and the importance of awareness. ↩

-

Explore the dangers of airborne latex allergens and how they can affect individuals even without direct contact. ↩

-

Gain insight into Type I allergic reactions caused by latex and how they can impact health. ↩

-

Discover the importance of maintaining an allergy-conscious inventory for customer safety and satisfaction. ↩

-

Find out how to partner with certified manufacturers to ensure the safety and compliance of balloon products. ↩

-

Learn about Sedex certification and how it ensures ethical practices in the supply chain. ↩

-

Discover the benefits of ISO 9001 certification for manufacturers in maintaining quality standards. ↩

-

Understand the significance of MSDS in ensuring product safety and compliance in the balloon industry. ↩

-

Explore effective strategies to prevent cross-contamination between latex and Mylar balloons in storage. ↩

-

Understand the CPSC regulations for labeling latex balloons to ensure compliance and safety. ↩

-

Learn about the CE mark and its importance in ensuring product safety and compliance in Europe. ↩