Latex vs Mylar Balloons: Which requires more specialized equipment for inflation?

Struggling with hidden equipment costs for balloons? The wrong choice means buying expensive, specialized inflators. Understanding their unique inflation needs is key to protecting your budget and streamlining operations.

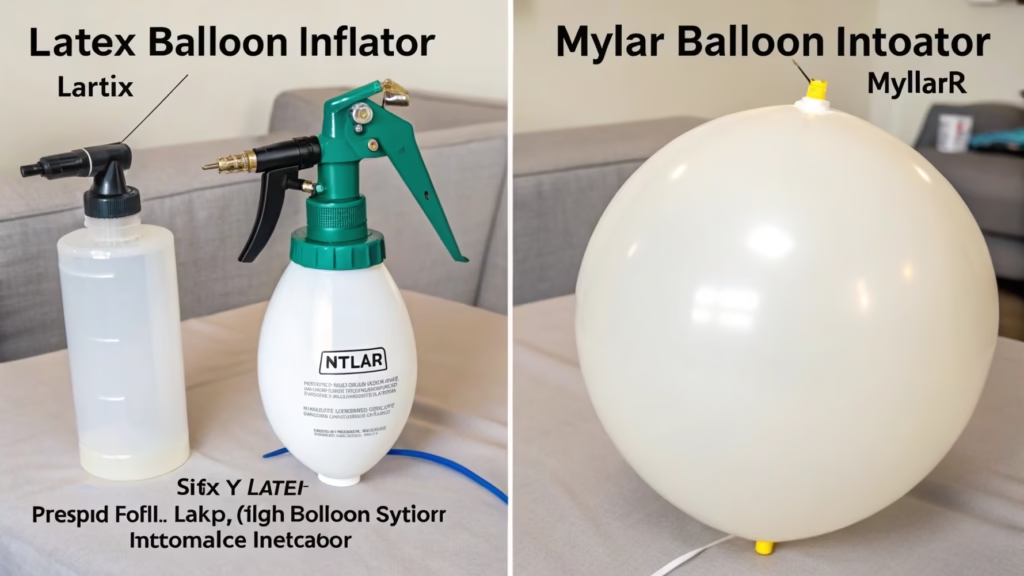

Mylar balloons require more specialized equipment.1 They need foil-specific inflator nozzles2 with an automatic shut-off to prevent bursting. Their material is less flexible than latex, which works well with standard pumps and high-pressure helium nozzles3, making latex more versatile for high-volume inflation.

So, mylar balloons need the special tools. But for a procurement manager focused on the big picture, the real questions go deeper. How does this affect your budget, your suppliers, and your storage efficiency? Let's explore the practical differences that impact your bottom line and overall supply chain.

Can a single helium tank be used to inflate both balloon types for wholesale purposes?

Managing multiple helium tanks is a logistical headache. This clutter increases costs and complexity in your warehouse. Using one tank for everything would simplify your entire operation and save valuable space.

Yes, you can use a single helium tank for both balloon types, but you will need different inflator nozzles. For latex, a standard high-pressure tilt valve works fine. For mylar, you need a specialized foil inflator with an automatic shut-off to prevent over-inflation and product loss.

From my experience in our factory, managing gas cylinders is all about efficiency. While the helium source is the same, the point of delivery—the nozzle—is critical. You absolutely can use one tank, but you must invest in a dual-regulator or interchangeable nozzles4. A standard latex inflator releases helium at a high pressure that will instantly pop a mylar balloon. The specialized mylar inflator, on the other hand, delivers a slower, controlled flow and shuts off automatically when the balloon is full. For large-scale operations, I've seen clients successfully use a single tank with a "Y" splitter hose, directing gas to two separate workstations—one for latex and one for mylar. This centralizes the helium supply while accommodating the specific needs of each material, which is a great compromise for efficiency.

What are the long-term cost differences when investing in inflators for latex vs. mylar?

Thinking about equipment costs? A cheap inflator might seem like a win now. But if it breaks down or damages inventory, the long-term costs in replacements and waste can damage your budget.

Initially, a standard latex inflator is cheaper. However, investing in a durable, dual-purpose inflator for both latex and mylar offers better long-term value. It reduces the need for multiple devices, minimizes training, and prevents costly mylar balloon wastage from improper inflation, saving money over time.

As a manufacturer, I look at costs over the product's entire lifecycle. The initial purchase is just one part of the equation.

| Inflator Type | Initial Cost | Durability | Key Feature | Long-Term Cost Consideration |

|---|---|---|---|---|

| Basic Latex Inflator | Low ($) | Medium | High-pressure nozzle | Frequent replacement may be needed. |

| Basic Mylar Inflator | Medium ($$) | Medium | Auto shut-off | Protects high-value mylar inventory. |

| Professional Dual Inflator | High ($$$) | High | Both nozzle types | Higher initial cost but lower replacement and waste costs. |

A cheap, plastic latex inflator might cost $20-$30, but you might replace it annually under heavy use. A professional-grade foil inflator starts around $100 but is built to last. The real savings with a foil inflator comes from preventing inventory loss. If a standard nozzle pops just a few large, licensed mylar balloons, you've already lost more than the cost of the proper tool. Investing in a robust, dual-nozzle system from the start is the most cost-effective strategy5 for any serious procurement plan.

Which balloon material offers a better durability and float time for event planners?

Event planners demand reliability. When balloons deflate too quickly, it reflects poorly on their service and your products. You need a balloon that looks great from the start to the end of any event.

Mylar balloons offer superior durability and float time6. Their non-porous material can keep them afloat for over a week, sometimes longer. Latex balloons are more fragile and typically float for only 8-12 hours without treatment, making mylar the more reliable choice for multi-day events.

We run float tests constantly in our quality control labs. The science is straightforward. Latex is a natural, porous material. Helium atoms are tiny and slowly escape through the pores of the latex. While a treatment like Hi-Float can extend this time, it's an extra step and cost. Mylar, or biaxially-oriented nylon, is a manufactured, non-porous film. The helium has a much harder time escaping, which is why it floats for so long. For a procurement manager, this means positioning mylar as the premium, worry-free option7 for clients like event planners8 who need guaranteed performance. I recently spoke with a large party retailer who bundles mylar balloons specifically for weekend events, marketing them as "Weekend Wonders" because they guarantee they'll last the entire celebration. That's turning a product feature into a direct sales advantage.

How do inflation requirements affect the bulk shipping and storage of latex and mylar balloons?

Worried about warehouse space? Bulky packaging can skyrocket your shipping and storage costs9. Choosing a product that ships and stores compactly is essential for maintaining a lean and efficient supply chain.

Latex balloons are more compact for shipping and storage. They are packaged uninflated in simple bags, taking up minimal space. Mylar balloons, while also shipped flat, are often larger and more rigid, requiring more careful handling and slightly more space per unit to prevent creasing or damage.

The difference in shipping and storage comes down to the material's nature. Latex is highly flexible. We can pack tens of thousands of latex balloons into a single master carton, maximizing container space and minimizing freight costs per unit. This density is a huge advantage for high-volume retailers. Mylar balloons, however, are more sensitive to damage before inflation. You can't just stuff them into a box. They need to be laid flat and packed carefully to avoid permanent creases or pinholes along the seams, which would cause them to leak after inflation. This means their packaging is often less dense. For procurement, this translates to slightly higher per-unit landed costs for mylar due to shipping and storage inefficiencies, a factor that must be included in your pricing models.

Conclusion

Ultimately, mylar balloons demand more specialized inflation tools to ensure product integrity, while latex offers more flexibility. Understanding these equipment and material differences helps you optimize costs and supply chain efficiency10.

-

Explore the essential tools for Mylar balloons to ensure proper inflation and prevent costly mistakes. ↩

-

Learn about the importance of foil-specific nozzles in preventing Mylar balloon damage during inflation. ↩

-

Understand how high-pressure helium nozzles work and their role in inflating latex balloons efficiently. ↩

-

Find out how dual-regulator systems can streamline balloon inflation processes and save costs. ↩

-

Learn about effective procurement strategies that can save costs and improve efficiency. ↩

-

Understand the differences in durability and float time to make informed choices for events. ↩

-

Discover why Mylar balloons are marketed as a premium choice for event planners seeking reliability. ↩

-

Understand the needs of event planners to better cater to their requirements for balloon quality. ↩

-

Find strategies to minimize shipping and storage costs for both latex and Mylar balloons. ↩

-

Explore methods to enhance supply chain efficiency in the balloon industry for better profitability. ↩