What factors are important when selecting a latex balloon manufacturer?

Are you struggling to find a reliable latex balloon supplier? Do you worry about product quality and delivery? Many buyers face these challenges.

Choosing the right latex balloon manufacturer is key to your business success. You need a supplier that offers consistent quality, reliable delivery1, and competitive pricing. Consider quality standards, production capacity, environmental certifications, and payment terms.

Finding the perfect partner for your latex balloon needs can feel overwhelming. There are so many options out there, each with different promises. Where do you even start to evaluate them? Let's break down the key factors that truly matter when you're making this crucial decision.

What quality standards should I look for in latex balloons?

Are you concerned about the quality of the balloons you buy? Poor quality can lead to unhappy customers and wasted money. What standards should you demand?

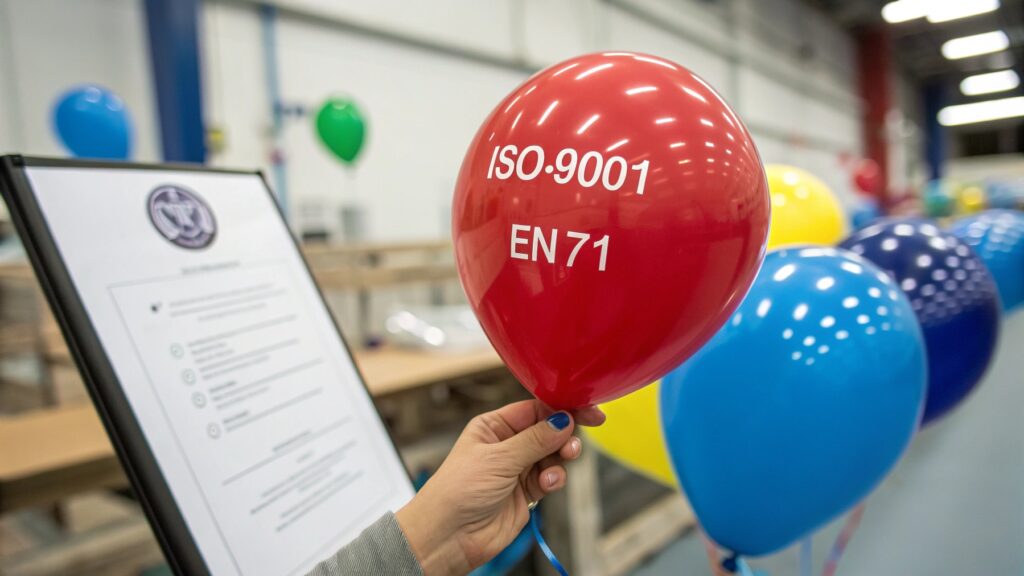

You should look for manufacturers who meet international quality standards. This includes certifications like ISO90012, which ensures consistent production processes. Also, check for compliance with safety regulations for toys, like EN713 or ASTM F9634, to guarantee product safety.

Quality is not just about how a balloon looks. It's about safety and reliability. Think about a time when you received a batch of balloons, and many popped easily or had strange colors. That is frustrating and impacts your reputation. I remember one shipment we received years ago where the balloons had an odd smell. We quickly learned the importance of checking for safety certifications. These certifications are not just pieces of paper. They mean the manufacturer has gone through strict testing and follows set rules.

Understanding Quality Certifications

Quality certifications show that a manufacturer cares about making good products.

- ISO9001: This is a global standard for quality management systems. It means the company has processes in place to ensure consistent quality.

- EN71: This is a European safety standard for toys. It covers things like chemical composition and flammability.

- ASTM F963: This is a US safety standard for toys. It has similar requirements to EN71.

Checking for these certifications gives you confidence that the balloons are safe and made to a high standard.

Importance of Raw Materials

The quality of latex balloons starts with the raw material.

| Raw Material | Importance | What to Look For |

|---|---|---|

| Natural Latex | Affects elasticity and strength | High-grade, responsibly sourced latex |

| Pigments | Determine color vibrancy and consistency | Non-toxic, fade-resistant pigments |

| Chemicals | Used for curing and anti-aging | Safe, approved chemicals in minimal amounts |

A good manufacturer uses high-quality natural latex and safe chemicals. This results in balloons that are durable, have bright colors, and are safe for use. Ask your supplier about their raw material sourcing and testing procedures.

How important is production capacity and lead time for balloon wholesalers?

Do you worry about getting your orders on time, especially during peak seasons? Can your supplier handle large orders? Production capacity5 and lead time are critical for your business.

Production capacity tells you if a manufacturer can meet your order volume. Lead time is how long it takes from order placement to delivery. For wholesalers, reliable capacity and short lead times are vital for managing inventory and fulfilling customer orders promptly.

Imagine you have a big holiday promotion coming up. You need thousands of balloons, and you need them by a specific date. If your supplier cannot produce enough or takes too long to ship, you will miss out on sales. This happened to a colleague once. They had a major event planned, and the balloons arrived a week late. The event was a disaster. That is why understanding a manufacturer's capacity and lead time is not just a detail; it is essential for planning and reliability.

Assessing Production Capacity

Production capacity is about whether a factory can make enough product.

- Factory Size: A larger factory often means more machines and workers, leading to higher capacity.

- Equipment: Modern and efficient machinery can produce more balloons faster.

- Labor Force: The number and skill of workers impact how much can be produced.

Ask the manufacturer about their daily or monthly production volume. Find out if they have handled similar order sizes to yours before. This helps you know if they can handle your needs, even when demand is high.

Understanding Lead Time

Lead time is about how fast you get your order.

| Stage | Typical Timeframe | Factors Affecting Time |

|---|---|---|

| Order Processing | 1-3 days | Supplier efficiency |

| Production | 7-20 days | Order size, current load |

| Quality Control | 2-5 days | QC process rigor |

| Shipping | Varies greatly | Location, shipping method |

Lead times can change based on the time of year. Peak seasons like holidays will have longer lead time6s. A reliable supplier will give you clear estimates and keep you updated. They should also have systems in place to manage unexpected delays. Building a good relationship with your supplier helps them understand your needs and prioritize your orders when possible.

What are the environmental certifications7 to consider for latex balloon manufacturers?

Are your customers asking for environmentally friendly products? Do you want to support sustainable practices? What certifications show a manufacturer is committed to the environment?

Look for manufacturers with environmental certifications. These show the company uses eco-friendly practices in production. Examples include ISO 14001 for environmental management systems or specific certifications related to sustainable latex sourcing.

More and more people care about the environment. They want to buy products that do not harm the planet. As a buyer, choosing suppliers who are environmentally responsible is becoming more important. It aligns with your customers' values and can improve your brand image. I remember when we first started looking into this. It felt like another layer of complexity. But we learned that manufacturers who care about the environment often care about overall quality and long-term sustainability, which is good for business.

Why Environmental Certifications Matter

Environmental certifications signal a manufacturer's commitment to reducing their impact.

- Reduced Waste: Certified companies often have programs to minimize waste in production.

- Energy Efficiency: They may use less energy or renewable energy sources.

- Responsible Sourcing: They might source latex from sustainably managed plantations.

Certifications like ISO 14001 mean the company has a system to manage its environmental impact. They regularly check and improve their environmental performance.

Types of Environmental Considerations

Beyond certifications, consider the materials and processes used.

| Area | What to Ask | Why It Matters |

|---|---|---|

| Raw Materials | Is the latex from sustainable sources8? | Reduces deforestation and protects ecosystems |

| Production Process | What chemicals are used? Is water recycled? | Minimizes pollution and conserves resources |

| Packaging | Is packaging minimal and recyclable? | Reduces landfill waste |

Ask the manufacturer about their environmental policies. Do they have specific goals for reducing their footprint? Supporting environmentally conscious suppliers helps protect the planet and meets growing customer demand for sustainable products.

How do I evaluate pricing and payment terms with a latex balloon supplier?

Is getting the best price your only concern? How do payment terms affect your cash flow? Evaluating pricing and terms is more than just looking at the number on the invoice.

When evaluating pricing, compare the cost per balloon, including all fees and shipping. For payment terms, look at the credit period offered. Favorable terms, like net 30 or net 60, can significantly help manage your cash flow. Balance competitive pricing with the supplier's reliability and quality.

Price is always a major factor, right? But the lowest price is not always the best deal. I learned this the hard way early in my career. I chose a supplier based purely on the lowest price. The quality was inconsistent, and shipments were often late. The money I saved was lost in dealing with returns and unhappy customers. Evaluating pricing means looking at the total cost, including quality and service. Payment terms9 are also crucial. They affect how you manage your money and plan your finances.

Analyzing the Price

Look beyond the per-unit cost.

- Total Cost10: Include shipping costs, taxes, and any other fees.

- Minimum Order Quantity (MOQ)11: Does their MOQ fit your needs? A low price might come with a high MOQ you cannot meet.

- Volume Discounts: Are there better prices for larger orders?

Get a detailed quote that breaks down all the costs. Compare quotes from different suppliers side by side. Make sure you are comparing apples to apples.

Understanding Payment Terms

Payment terms dictate when you need to pay.

| Term | Meaning | Benefit to Buyer |

|---|---|---|

| Payment in Advance | Pay before shipment | Not ideal for buyer cash flow |

| Net 30 | Payment due 30 days after the invoice date | Allows time to receive and sell product |

| Net 60 | Payment due 60 days after the invoice date | Provides more flexibility for cash flow |

| Letter of Credit | Bank guarantees payment under certain terms | Offers security for both buyer and seller |

Favorable payment terms give you more time to pay after receiving the goods. This helps your cash flow. Discuss terms with potential suppliers and see what they offer. A supplier willing to work with you on terms can be a valuable partner. Remember, building a strong relationship can sometimes lead to better terms over time.

Conclusion

Choosing a latex balloon manufacturer requires looking at many things. Focus on quality certifications, production ability, environmental efforts, and fair pricing with good terms.

-

Learn about effective strategies to guarantee timely delivery from suppliers, crucial for your business success. ↩

-

Understanding ISO9001 can help you choose manufacturers that ensure quality and consistency in their products. ↩

-

Exploring EN71 compliance will inform you about safety standards that protect consumers, especially children. ↩

-

Learning about ASTM F963 will help you understand safety regulations that manufacturers should follow for toys. ↩

-

Learning about production capacity can help you choose suppliers that meet your business needs, especially during peak seasons. ↩

-

Exploring this topic will provide insights into managing expectations and ensuring timely delivery for your orders. ↩

-

Understanding these certifications helps you choose eco-friendly suppliers and meet customer demands for sustainable products. ↩

-

Learn about the significance of sustainable sourcing in protecting ecosystems and promoting responsible production practices. ↩

-

Exploring payment terms can enhance your cash flow management, allowing for better financial planning and supplier relationships. ↩

-

Understanding total cost helps you make informed decisions, ensuring you consider all expenses, not just the price tag. ↩

-

Knowing about MOQ can prevent overcommitting to orders that don't fit your needs, saving you money and hassle. ↩