How Do I Test the Quality of a Latex Balloon Sample?

Are you stressed about buying balloons? Do you worry about their quality? Relax, testing them is easier than you think!

To test a latex balloon sample's quality, you should check its color, weight, size, smell, cleanliness, air tightness1, and elasticity2. These simple checks can reveal a lot about the balloon's material and how well it was made.

It is important to know how to check balloon samples. This helps you pick the best ones for your business. I want to share some easy ways to do this.

How Can You Determine the Burst Strength of a Latex Balloon?

Do you need balloons that won't pop easily? Are you worried about balloons bursting during use? Finding strong balloons is key.

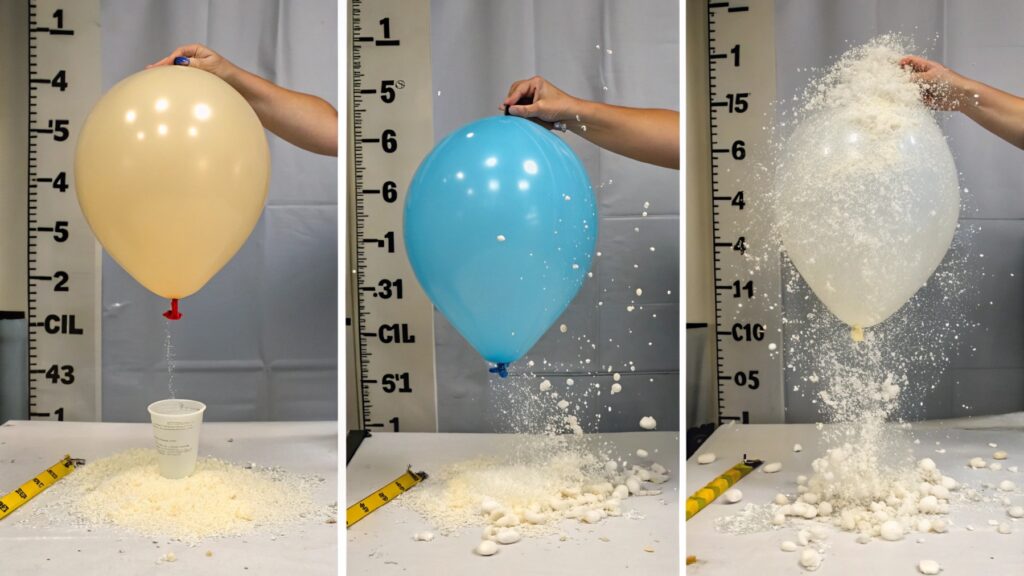

You can determine the burst strength3 of a latex balloon by inflating it until it pops. Note the size it reaches before bursting. A larger size before popping suggests higher burst strength.

Testing burst strength helps you see how durable the balloons are. This is important for safety and customer happiness. Let me tell you more about this.

Burst strength is about how much air a balloon can hold before it breaks. It shows how tough the latex is. Here is how you can think about it:

- Inflation: Blow up the balloon slowly. Watch it closely.

- Size: See how big it gets. Measure the diameter if you can.

- The Pop: The moment it pops tells you its limit.

Think about these points when testing:

| Test Aspect | What to Look For | Why it Matters |

|---|---|---|

| Inflation Speed | Inflate at a steady rate | Helps get a true measure of strength |

| Final Size | How large the balloon is right before it pops | Bigger size often means stronger latex |

| Type of Pop | Does it pop with a bang or just tear? | A clean pop suggests good material quality |

| Multiple Samples | Test several balloons from the batch | Ensures consistency in quality across the samples |

Testing several balloons gives a better idea of the batch's overall strength. If some pop very quickly, the batch might be weak. This test is simple but very useful for checking quality.

What Methods Are Used to Check the Elasticity and Flexibility of Latex Balloons?

Do you want balloons that stretch well? Is flexibility important for your use? Testing how stretchy a balloon is matters.

You can check the elasticity and flexibility of latex balloons4 by stretching them before inflating. Gently pull the balloon material. It should stretch easily and return to its shape without feeling stiff or cracking.

Good elasticity5 means the balloon will inflate smoothly and hold air well. It also makes tying easier. Let me explain how I check this.

Elasticity and flexibility show the quality of the latex material6. Good latex is like a strong rubber band. It stretches far and snaps back. Bad latex might feel stiff or break when stretched. Here is how I test this:

- Pre-inflation Stretch: Before you blow it up, grab the neck and the top. Gently pull it apart. Does it stretch smoothly? Does it feel soft or hard?

- Neck Stretch: Stretch the neck of the balloon. This part needs to be flexible for tying knots. Does it stretch without thinning too much?

- Return to Shape: After stretching, does the balloon go back to its original size and shape quickly? Or does it stay stretched out?

Consider these details when checking:

| Test Method | What to Observe | Sign of Good Quality |

|---|---|---|

| Gentle Pull | How far does it stretch before resistance? | Stretches a good distance easily |

| Feel of Material | Is it smooth and soft or rough and brittle? | Smooth and flexible feel |

| Snap Back Test | How quickly does it return to its original size? | Snaps back quickly and completely |

| Consistency | Is the stretch the same across different parts? | Even stretch throughout the balloon |

Checking elasticity helps you avoid balloons that are hard to inflate or tie. It also hints at how long the balloon will stay inflated. A flexible balloon is usually a good sign.

How Do You Identify Defects or Inconsistencies in the Material of a Latex Balloon Sample?

Do you want perfect-looking balloons? Are you worried about finding flaws? Spotting defects is crucial for quality.

To identify defects7 or inconsistencies in the material of a latex balloon sample, visually inspect each balloon closely. Look for uneven color, thin spots, holes, tears, or strange marks on the surface before and after inflation.

Finding defects early saves you trouble later. No one wants to use faulty balloons. Here is what I check for.

Material quality is everything for a good balloon. Defects can cause leaks or early popping. They also make the balloon look bad. Here is my process for spotting problems:

- Before Inflation: Hold the uninflated balloon up to the light. Look through it. Are there areas that look thinner than others? Are there pinholes or tiny tears?

- Color Check: Is the color even all over? Are there dark or light spots? Does the color match the sample?

- Surface Feel: Run your fingers over the surface. Does it feel smooth? Are there bumps or rough spots?

- After Partial Inflation: Blow it up a little. Thin spots will stretch more and look lighter. This makes them easier to see.

Pay attention to these possible flaws:

| Type of Defect | What it Looks Like | Why it Matters |

|---|---|---|

| Thin Spots | Areas that are lighter when held to light | Will likely pop early or leak |

| Pinholes/Tears | Small holes or rips | Causes the balloon to deflate quickly |

| Uneven Color | Patches of different shades | Looks bad, might indicate poor mixing of latex |

| Surface Blemishes | Strange marks, bumps, or rough areas | Affects appearance, could weaken the material |

Checking for defects8 is a visual job. Take your time and look at each balloon carefully. It helps ensure you get a batch of high-quality balloons.

What Accelerated Aging Tests Can Assess the Shelf Life of Latex Balloons?

Are you concerned about how long balloons will last? Do you need to know their shelf life? Aging tests can help predict this.

Accelerated aging tests9 for latex balloons typically involve exposing them to high heat and controlled humidity for a set period. This process simulates the effects of long-term storage, allowing manufacturers to estimate how well the balloons will hold up over time.

Knowing the shelf life is important for managing inventory and ensuring customer satisfaction. Balloons shouldn't degrade too quickly. Let me tell you about these tests.

Accelerated aging is like fast-forwarding time for the balloons. Heat is often used because it makes chemical reactions happen faster. This helps predict how the latex will change over months or years of storage. Here is the general idea:

- Test Conditions: Balloons are put in a special oven or chamber. The temperature is set higher than normal room temperature. Humidity might also be controlled.

- Time Period: They stay in these conditions for a specific amount of time. This time is much shorter than the actual shelf life, but the heat speeds things up.

- Post-Aging Test: After the test, the balloons are taken out. They are then tested for burst strength, elasticity, and appearance.

Look at these aspects after the aging test:

| Post-Aging Test | What to Check | Sign of Good Shelf Life |

|---|---|---|

| Burst Strength | How much strength did the balloons lose? | Strength loss is minimal or within acceptable limits |

| Elasticity | Do they still stretch well? | Material remains flexible and returns to shape |

| Appearance | Is there cracking, stickiness, or discoloration? | No significant changes in appearance |

| Inflation Test | Do they still inflate without issues? | Inflates smoothly without becoming brittle |

Accelerated aging tests are usually done by manufacturers in their labs or by third-party labs. While you might not do this test yourself, asking for the results shows you care about long-term quality. It helps ensure the balloons will be good when your customers buy them.

Conclusion

Checking latex balloon samples involves simple steps: look at color, weight, size, smell, and feel. Test air tightness and stretchiness.

-

Learning about air tightness testing can help you ensure that your balloons will last longer and perform better at events. ↩

-

Exploring the role of elasticity in balloons can enhance your knowledge about their durability and performance. ↩

-

Understanding burst strength is crucial for selecting durable balloons that won't pop easily during events. Explore this link for detailed insights. ↩

-

Testing elasticity and flexibility is key for selecting the right balloons for your needs. Discover effective methods to evaluate them. ↩

-

Understanding good elasticity is essential for selecting high-quality balloons that inflate smoothly and hold air well. ↩

-

Exploring the properties of latex material can help you choose balloons that are durable and flexible, ensuring better performance. ↩

-

Learning how to identify defects in latex balloons is crucial for ensuring you get the best quality for your needs. ↩

-

Learn effective techniques for identifying defects in balloons to ensure high quality and safety for your events. ↩

-

Discover how accelerated aging tests can help manufacturers ensure the longevity of latex balloons, making them a reliable choice for events. ↩