What should I look for in a latex balloon supplier’s quality control?

Worried about balloon quality issues impacting your brand? Inconsistent colors and safety risks can cost you dearly. The right quality control checks are your best defense.

Look for a supplier with key certifications like ISO 90011 and Sedex2, rigorous raw material testing, and documented in-process checks. These include inflation tests3, color consistency4 reviews, and verification of ink safety5. A strong quality management system (QMS)6 is non-negotiable for reliable partnership.

These initial checks are just the starting point. But a truly reliable supplier goes much deeper into their quality processes. Let’s break down the specific certifications, material checks, and testing procedures you need to know about. This will give you the confidence to choose a partner who protects your brand and your customers.

What quality certifications are essential for a balloon manufacturer?

Confused by all the different certifications? Choosing a supplier without the right ones puts your business at risk. Focus on these essential documents to ensure compliance and safety.

Essential certifications include ISO 9001 for quality management, Sedex or BSCI7 for ethical sourcing8, and compliance with EN-719 (Europe) and ASTM F96310 (USA) for toy safety. These prove a manufacturer's commitment to consistent quality, ethical practices, and product safety for consumers.

As a procurement manager, you need more than just a supplier's word. You need proof. Certifications are that proof. They show that an independent third party has audited the manufacturer's processes and confirmed they meet global standards. We find that our most successful partnerships are with clients who ask for these documents upfront. It shows they are serious about quality, just like we are.

Why Certifications Matter More Than Promises

A promise is just words, but a certification represents a system. An ISO 9001 certification, for example, proves that we have a robust Quality Management System (QMS). It means every step, from raw material intake to final packing, is documented, controlled, and traceable. This isn't just for us; it’s for you. It gives you assurance that you will receive the same high-quality product with every single order.

| Certification | What It Covers | Why It Matters for You |

|---|---|---|

| ISO 9001 | Quality Management Systems | Ensures consistent product quality and process control. |

| Sedex/BSCI | Ethical Trade & Social Compliance | Protects your brand's reputation and ensures worker welfare. |

| EN-71 / ASTM F963 | Toy Safety Standards | Guarantees balloons are safe for children, free from harmful chemicals. |

How is the quality and sourcing of the raw latex verified?

Does poor latex quality lead to weak, unreliable balloons? Cheap materials break easily and disappoint customers. A supplier must verify their latex source to guarantee performance and safety.

A top supplier verifies raw latex quality11 through Certificates of Analysis (COA) from their source and in-house testing. They check for purity, protein levels, and chemical composition12. This ensures the final product is strong, elastic, and free from harmful substances before production even begins.

The quality of a balloon begins with the quality of the tree sap. Not all natural latex is created equal. We've learned over 37 years that you cannot leave this to chance. A good supplier builds long-term relationships with reputable latex plantations. This ensures a consistent supply of high-grade material. But we don't just trust our partners; we verify. Every single shipment of raw latex that arrives at our facility undergoes a strict intake protocol before it's ever approved for use in our production line. This is a non-negotiable step.

From Plantation to Production Line

The journey starts with demanding a Certificate of Analysis (COA)13 for every batch. This document details the technical specifications, but we don't stop there. Our in-house lab runs its own tests to confirm the data. We check things like total solids content and viscosity, which directly impact the balloon's wall thickness and strength. If a batch doesn't meet our standards, we reject it. This strict gatekeeping prevents problems before they start and is a critical part of our commitment to you.

| Verification Step | Purpose | Impact on Final Balloon |

|---|---|---|

| Supplier Vetting | Ensure ethical and sustainable sourcing. | Consistent, high-quality raw material supply. |

| Certificate of Analysis | Confirms seller's quality claims. | Initial check for purity and composition. |

| In-House Lab Testing | Verifies COA and tests key properties. | Guarantees strength, elasticity, and safety. |

What are the standard procedures for inflation and burst-pressure testing?

Fearful of customer complaints about balloons popping too easily? Weak balloons ruin events and damage your reputation. Standardized testing is the only way to ensure durability and customer satisfaction.

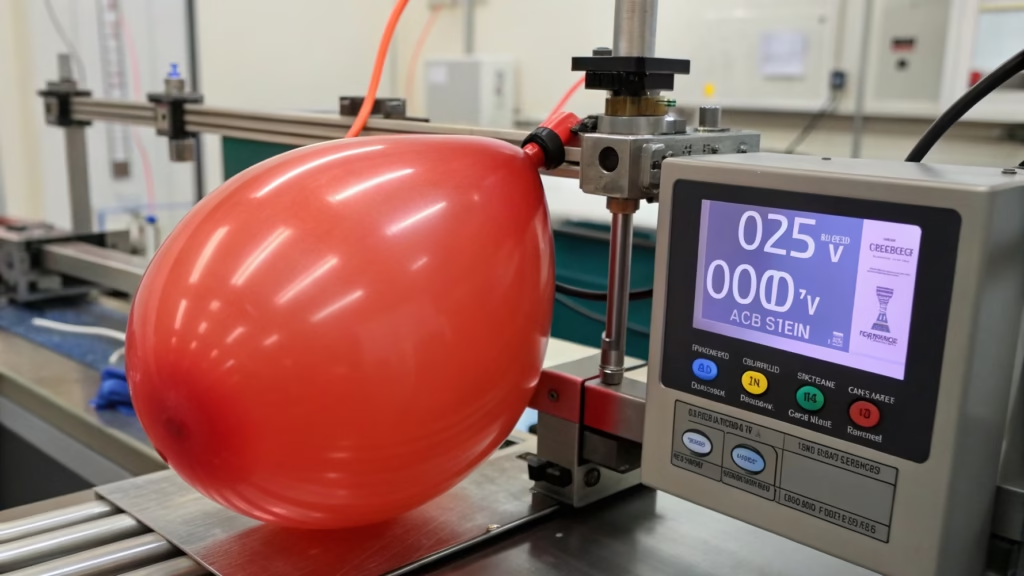

Standard procedures involve randomly sampling balloons from each batch for automated inflation tests. These machines measure the balloon's maximum volume and the pressure it withstands before bursting. The data is compared against strict internal benchmarks to ensure every batch meets durability and size specifications.

Every production run consists of thousands of balloons. How can you be sure the first balloon is as good as the last? The answer lies in systematic, data-driven testing. We pull samples at regular intervals throughout the production process based on established statistical methods like AQL (Acceptable Quality Limit)14. These samples are not just visually inspected; they are put through physical tests to measure their performance under stress. This goes far beyond just a simple manual inflation check to see if it holds air.

Data-Driven Quality Control

We use specialized equipment to inflate sample balloons at a controlled rate until they pop. The machine records the exact volume and internal pressure at the moment of failure. This data tells us everything we need to know about the balloon's strength and elasticity. By tracking these metrics, we can spot any variations in the production process immediately. For a procurement manager, this data is your guarantee that the balloons you order won't just look good; they will perform reliably for your customers every time.

| Testing Metric | What It Measures | Why It's Important for Buyers |

|---|---|---|

| Maximum Inflation Volume | The point of failure in terms of size. | Ensures balloons reach advertised size without popping. |

| Burst Pressure (PSI) | The amount of pressure the latex can handle. | Indicates material strength and durability. |

| Inflation Time / Rate | How consistently the balloon inflates. | Reflects uniform wall thickness and quality. |

How do suppliers ensure color consistency and ink safety for printed balloons?

Frustrated by color variations between balloon batches? Mismatched colors ruin displays and look unprofessional. Strict color and ink controls are necessary for brand consistency and safety.

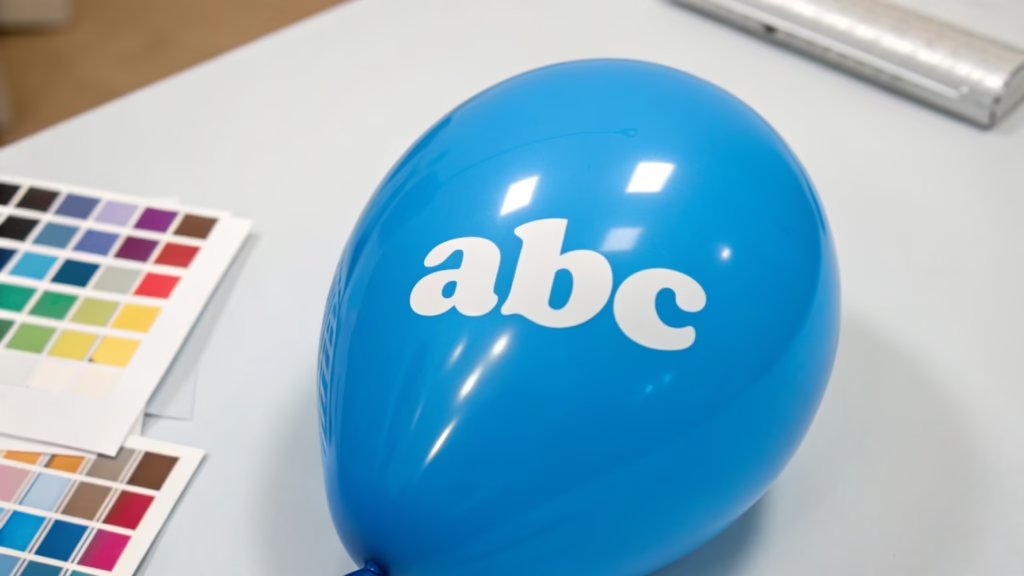

Suppliers ensure color consistency4 using a spectrophotometer15 to match batches against a master color standard (like Pantone). For printing, they use inks that are certified non-toxic and compliant with safety standards like EN-71. Regular ink batch testing16 ensures ongoing safety and print quality.

When your brand's logo is on a balloon, color accuracy is everything. A shade of red that is slightly off can misrepresent your brand identity. That’s why relying on the human eye is not enough. We use digital tools to ensure precision. For printed balloons, the focus shifts to safety. The ink that makes a logo vibrant must also be completely safe for end-users, especially children. These two areas—color and ink—require their own dedicated quality control procedures.

The Science of Perfect Color and Safe Ink

For color, we use a spectrophotometer15. This device analyzes color digitally, removing all human subjectivity. We compare every batch of colored latex against an approved master standard, often matched to a Pantone color code. This ensures that the balloons you order in June will be the exact same color as the ones you ordered in January. For ink, we only source from suppliers who can provide documentation that their products are non-toxic and free of heavy metals, meeting EN-71 standards. We also perform our own "tape tests17" to ensure the ink adheres properly and won't flake off.

| Quality Check | Method | Benefit for Your Business |

|---|---|---|

| Color Consistency | Spectrophotometer comparison to Pantone standards. | Guarantees brand colors are accurate across all orders. |

| Ink Adhesion Test | "Tape test" to check if ink flakes off. | Ensures printed logos stay intact and look professional. |

| Ink Chemical Analysis | Lab testing for heavy metals and toxins. | Protects consumers, especially children, and ensures compliance. |

Conclusion

Evaluating a supplier's quality control is about verifying their systems. Look for certifications, raw material checks, product testing, and color control to ensure a safe, reliable, and high-quality partner.

-

Explore this link to understand how ISO 9001 ensures quality management and consistency in products. ↩

-

Learn about Sedex certification and its role in promoting ethical sourcing and social compliance. ↩

-

Discover how inflation tests ensure the durability and performance of balloons. ↩

-

Learn about the methods used to ensure consistent colors across balloon batches. ↩ ↩

-

Understand the importance of ink safety standards in protecting consumers, especially children. ↩

-

Discover how a QMS ensures consistent quality and process control in manufacturing. ↩

-

Discover how BSCI certification helps ensure ethical trade practices and worker welfare. ↩

-

Learn about the significance of ethical sourcing in maintaining brand reputation. ↩

-

Find out how EN-71 standards protect consumers, especially children, from unsafe toys. ↩

-

Understand the significance of ASTM F963 in ensuring the safety of toys and related products. ↩

-

Learn about the processes that ensure the quality and safety of raw latex used in balloons. ↩

-

Find out how testing chemical composition ensures the safety and quality of products. ↩

-

Explore the importance of COA in verifying the quality of raw materials. ↩

-

Understand how AQL helps maintain quality standards in production processes. ↩

-

Explore how spectrophotometers help maintain color accuracy in balloon manufacturing. ↩ ↩

-

Learn about the role of ink batch testing in ensuring print quality and safety. ↩

-

Discover how tape tests verify the durability of printed logos on balloons. ↩