What’s the Science Behind Hi-Float, and How Does It Triple a Balloon’s Float Time?

Your latex balloons droop too quickly, disappointing clients. This means lost profits and unhappy customers. Hi-Float solves this by making your arrangements last much longer, keeping everyone happy.

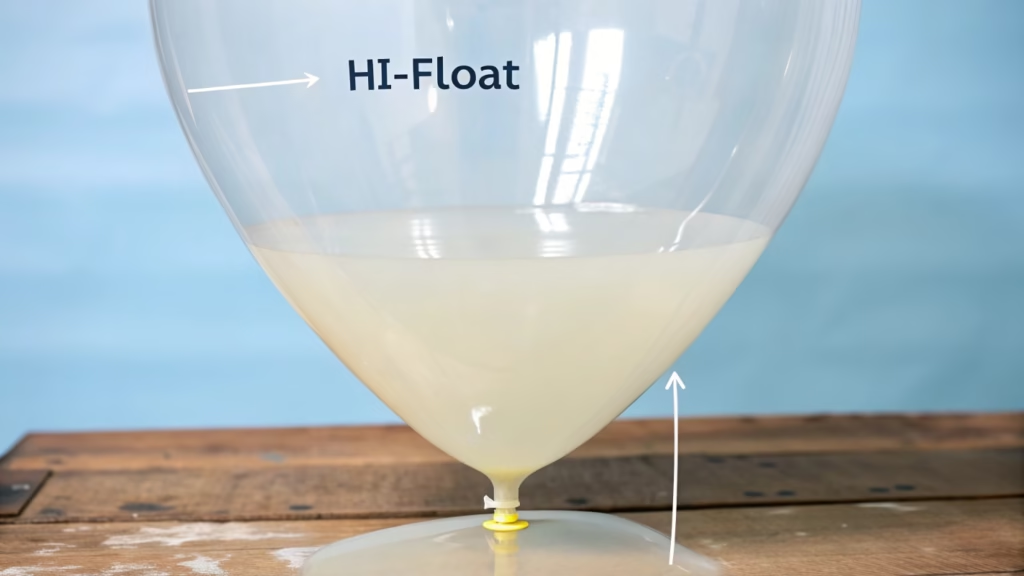

Hi-Float is a liquid sealant1 that you put inside a latex balloon. It dries into a plastic-like coating. This coating seals the tiny pores in the latex, which keeps the helium2 from escaping so quickly. This can make balloons float up to 25 times longer.

I’ve spent years in the balloon industry, both in management and on the production floor. I’ve seen firsthand how product performance affects a business's bottom line. Understanding the science behind a product like Hi-Float isn't just for chemists; it's for anyone who wants to deliver better value and build a stronger business. This simple liquid can fundamentally change how you work with latex balloons. Let's look at how this impacts your operations and profitability3.

How can using Hi-Float improve the profitability of balloon arrangements?

Do you rush to create balloon arrangements4 right before an event? This last-minute work is stressful and limits your capacity. Using Hi-Float lets you prepare designs days ahead, boosting efficiency.

Hi-Float dramatically increases profitability by extending the life of your balloon arrangements. This allows you to prepare for events well in advance, reducing last-minute labor costs5. Longer-lasting displays also command higher prices and encourage repeat business from satisfied customers, directly boosting your revenue.

As a procurement manager, you are always looking for ways to improve efficiency and reduce costs. Using Hi-Float is a direct path to better profitability. Longer-lasting balloon displays mean you can prepare them days in advance. This smooths out your workflow and cuts down on overtime labor costs associated with last-minute preparations. I remember a large retail partner who was struggling with event setups6. Once they started using Hi-Float, their labor costs for balloon decor dropped by nearly 30% because they could schedule their staff more effectively. The longer float time also means your creations look better for longer, which justifies a higher price point. This enhances the perceived value and customer satisfaction7. Satisfied clients are more likely to become repeat customers, providing a stable revenue stream.

Key Profit Drivers with Hi-Float

| Benefit | Impact on Profitability |

|---|---|

| Longer Display Life | Justifies premium pricing for arrangements. |

| Advance Preparation | Reduces last-minute labor and overtime costs. |

| Increased Capacity | Allows you to take on more orders without more staff. |

| Enhanced Reputation | Builds a brand known for quality and reliability. |

What are the safety and chemical properties of Hi-Float for bulk shipping?

Are you worried about shipping and storing new chemical products? Safety and compliance are major concerns when adding new items to your inventory. Hi-Float is designed to be safe and easy to handle.

Hi-Float is a non-toxic8, non-flammable, and water-based solution. It is completely safe for bulk shipping by air, sea, or land without special handling requirements. Its chemical properties are similar to craft glue, making it safe for both staff and customers when used as directed.

At AIHUA BALLOON, we handle international logistics every day. We understand that our partners, like you, need products that are safe and simple to transport. Hi-Float meets these requirements perfectly. It's essentially a water-soluble plastic solution, much like a liquid adhesive. Because it is water-based, it has no flash point and is not considered a hazardous material. This is crucial for keeping shipping costs low and avoiding complex customs paperwork. We ship it globally without any issues. The product is also biodegradable9 and non-irritating. When I was visiting a large distributor in Europe, their warehouse manager was relieved to learn he didn't need any special storage facilities for it. He could just place it on the shelf next to other party supplies. This simplicity is a huge benefit when you manage a large and diverse inventory.

Hi-Float Safety Profile

| Property | Description | Implication for Procurement |

|---|---|---|

| Composition | Water-based, non-toxic liquid plastic | Safe for employees to handle. |

| Flammability | Non-flammable | No special fire-proof storage needed. |

| Toxicity | Non-toxic and non-irritating | Low risk for staff and end-users. |

| Shipping Class | Not classified as hazardous goods | Standard, low-cost shipping methods can be used. |

Are there different Hi-Float formulas for different types of balloons?

Do you wonder if you need different products for different balloon types? Managing too many product variations can complicate your inventory. Luckily, the solution here is simple and efficient.

No, there is one primary Hi-Float formula designed specifically for standard latex balloons. There is also a "Super Hi-Float" version that offers slightly longer float times. However, Hi-Float should never be used in foil (Mylar) or plastic bubble balloons as it is not effective.

From a manufacturing and supply chain perspective, simplicity is key. The makers of Hi-Float understood this. They developed a versatile formula that works across the vast majority of latex balloons you stock, from small 9-inch rounds to large 36-inch giants. This streamlines your procurement process because you only need to order and manage one core product. The standard Hi-Float is the go-to for most applications. Super Hi-Float is available for situations that demand the absolute maximum float time, like multi-week displays. It's important to remember that Hi-Float is designed to seal the porous surface of latex. Foil balloons are made of a non-porous nylon sheet, so Hi-Float provides no benefit and can make them too heavy to float. This clear distinction helps prevent ordering errors and misuse.

Hi-Float Product Guide

| Product | Recommended Balloon Type | Key Use Case |

|---|---|---|

| Standard Hi-Float | All standard latex balloons | General use for events, parties, and retail. |

| Super Hi-Float | All standard latex balloons | When maximum float time is critical. |

| Not Recommended | Foil (Mylar), Plastic (Bubble) | The material is non-porous; Hi-Float is ineffective. |

What is the recommended application process10 to guarantee extended float time?

Are you concerned that your team won't use the product correctly? Improper application can lead to wasted product and poor results. Following a few simple steps guarantees success every time.

For best results, add the correct amount of Hi-Float based on the balloon size using the pump dispenser. Rub the balloon gently to spread the liquid into a thin, even coating inside. Inflate with helium, then let the balloon dry for a few hours.

I believe that great results come from great processes. The application of Hi-Float is a perfect example. The goal is to create a complete, uniform barrier inside the balloon. Using the right amount is the first step. The manufacturer provides a chart and a pump system that dispenses the correct dose for each balloon size. This removes all guesswork. After dispensing the liquid, the next critical step is to gently rub the balloon's exterior to spread the coating. You should not be able to see any clumps or bare spots. Once coated, you can inflate the balloon with helium. It is important to handle the treated balloon carefully and keep it in a climate-controlled environment while it dries. This ensures the coating sets properly and delivers the promised float time.

Step-by-Step Application Guide

| Step | Action | Why It's Important |

|---|---|---|

| 1. Dispense | Use the Hi-Float pump to add the recommended amount. | Ensures there is enough liquid to coat the balloon without adding excess weight. |

| 2. Spread | Gently rub the balloon between your hands until the inside is fully coated. | Creates a uniform barrier, which is key to preventing helium leaks. |

| 3. Inflate | Fill the balloon with helium to its proper size. | The air pressure helps the coating spread and dry against the latex wall. |

| 4. Dry | Allow the balloon to air dry for at least two hours before use. | The coating must be fully dry to form an effective gas barrier. |

Conclusion

Hi-Float is a simple, safe, and highly effective tool. It extends balloon float time, which increases your profitability and customer satisfaction. Correct application is the key to unlocking its full potential.

-

Discover the role of liquid sealants in improving the longevity of balloon displays. ↩

-

Understand the science behind helium and its impact on balloon arrangements. ↩

-

Find strategies to boost your business's bottom line through effective balloon decor. ↩

-

Get tips and tricks for designing eye-catching balloon displays that impress clients. ↩

-

Explore methods to cut down on labor expenses while maintaining quality decor. ↩

-

Find out how to streamline your event setup process for better efficiency. ↩

-

Discover ways to enhance client experiences and encourage repeat business. ↩

-

Learn why non-toxic materials are essential for safe event environments. ↩

-

Understand the importance of sustainability in the event decoration industry. ↩

-

Learn the step-by-step method to ensure optimal results with Hi-Float. ↩