Why do mylar balloons last longer than regular helium balloons?

You know that feeling when a party ends and your beautiful latex balloons already look deflated? Frustrating, right? But then you see those shiny mylar balloons, still floating high days later. What's their secret?

Mylar balloons1 last longer than regular helium balloons2 mainly because of their different material and construction. Mylar is a type of plastic film3 that is far less permeable to helium gas than the latex rubber used in traditional balloons, which has tiny pores that allow gas to escape over time.

It is true. You see the big difference between how long mylar balloons float and how long latex balloons float. Let's delve into why this happens.

How does the material of mylar balloons contribute to their extended float time?

Have you ever wondered what makes mylar balloons float for so long? It all comes down to the material they are made from.

Mylar balloons use a special type of plastic film that creates a superior barrier against gas leakage4 compared to the porous nature of latex. This material significantly reduces the rate at which helium can escape, allowing the balloon to stay inflated for much longer.

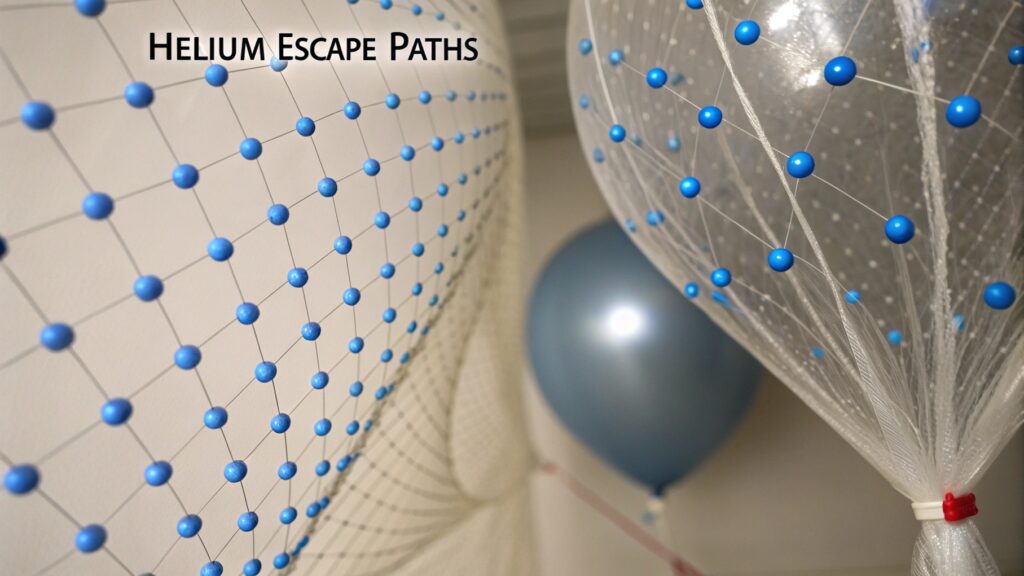

From my experience in the balloon industry5, I understand materials deeply. Standard latex balloons are made from natural rubber. This rubber has microscopic pores6. These small holes are like tiny one-way doors. They let helium molecules7 pass through. Helium atoms are very small. They can slip out of these pores. Think of it like air slowly leaking from a bicycle tire. It is not a sudden burst. It is a slow, steady escape.

Mylar balloons are very different. They are made from biaxially-oriented polyethylene terephthalate, or BoPET film8. We often call it Mylar. This film is a type of plastic. It is not porous like latex. Instead, it forms a solid, non-permeable barrier9. This barrier traps the helium inside. This means very few helium atoms can escape. This is why mylar balloons stay inflated for days, or even weeks. It is due to their material.

To illustrate, consider the differences in how these materials manage gas.

| Feature | Latex Balloons | Mylar Balloons |

|---|---|---|

| Material | Natural rubber | BoPET (Mylar) film |

| Pore Structure | Microscopic pores (porous) | Non-porous |

| Gas Permeability | High (helium escapes easily) | Low (helium escapes very slowly) |

| Typical Float Time | Hours to 1-2 days | Days to several weeks |

| Feel | Stretchy, pliable | Crisp, metallic |

This table makes it clear. The material itself is the main reason for the extended float time10 of mylar balloons. Our goal at AIHUA BALLOON is to make sure our products, whether latex or mylar, offer the best possible performance. We know that latex balloons will always have some permeability. We work to improve their gas retention as much as possible. For mylar, we focus on maintaining that excellent non-permeability.

What are the key differences in gas permeability11 between mylar and latex balloons?

Have you ever wondered why some balloons deflate so much faster than others? It boils down to something called gas permeability.

The main difference in gas permeability between mylar and latex balloons is that latex has a porous structure allowing helium molecules to easily pass through, while mylar is a non-porous plastic film that acts as a much stronger barrier, trapping the gas inside for longer.

From my understanding of material science12, gas permeability is a crucial concept. It tells us how easily a gas can pass through a material. Think of it as a gate. Some gates are wide open. Some are nearly closed.

Latex is a material with a high gas permeability for helium. This is because latex rubber has a natural molecular structure that includes many very small gaps. These gaps are not visible to the naked eye. But they are large enough for tiny helium atoms to pass through. When you inflate a latex balloon with helium, these helium atoms are constantly pushing against the inner surface of the balloon. They find these tiny gaps. They then escape into the surrounding air. This process is called diffusion13. It happens continuously. The balloon slowly deflates as helium diffuses out.

Mylar, on the other hand, has very low gas permeability for helium. This is because mylar film is a type of stretched plastic. Its molecular structure is tightly packed. This leaves very few, if any, openings large enough for helium atoms to pass through. It is like trying to push a basketball through a keyhole. It simply will not fit. The mylar material forms an almost impenetrable barrier to helium. This allows the gas to stay inside the balloon for a much longer time.

Let's look at the permeability aspects more closely:

| Permeability Factor | Latex Balloons | Mylar Balloons |

|---|---|---|

| Atomic Size Fit | Helium atoms can fit through molecular gaps | Helium atoms cannot fit through tight structure |

| Diffusion Rate | High (fast helium loss) | Very low (minimal helium loss) |

| Barrier Strength | Weak (porous structure) | Strong (non-porous barrier) |

| Material State | Elastomer (stretchy, breathable) | Polymer film (rigid, impermeable) |

| Environmental Impact | More sensitive to temperature changes, which can affect permeability | Less sensitive to temperature changes, maintaining integrity |

I spend a lot of time reviewing quality reports. These reports confirm what we see in practice. Latex balloons will always lose helium. It is a property of the material. Our work at AIHUA BALLOON involves making sure our latex balloons have the best possible seal at the neck. We work to make the latex strong, reducing leakage everywhere possible. For mylar, the material itself does most of the work. Our focus there is on strong seams. We ensure these seams are perfectly sealed. This means no helium escapes anywhere. The permeability of the material is key. Mylar wins the permeability battle hands down.

Do mylar balloons' metallic coating14 play a role in preventing helium escape?

Have you ever noticed that shiny metallic look of mylar balloons and wondered if it serves a purpose beyond just aesthetics? It does.

Yes, the metallic coating on mylar balloons plays a significant role in preventing helium escape. This thin layer of aluminum acts as an additional, highly effective barrier to gas diffusion, further reinforcing the plastic film's already low permeability and ensuring the contained helium is sealed in more securely.

From my knowledge, the metallic coating on mylar balloons is not just for looks. It is a very important part of their design. Most mylar balloons have a thin layer of metallic aluminum on their surface. This layer is applied during manufacturing. It is incredibly thin. It is almost at the atomic level. This metallic layer is vacuum-metallized onto the BoPET plastic film.

This aluminum layer acts as an extra barrier. It works extremely well to block gases. Metals, like aluminum, are non-porous. Their atomic structure is very dense. This means there are no gaps for helium to pass through. So, even if there were any tiny imperfections in the plastic film itself, the metallic coating covers them. It adds another layer of protection. It is like putting an extra seal on a container. This double barrier system—plastic film plus metallic layer—makes mylar balloons almost completely impermeable to helium.

This is different from how some other balloons handle gas retention.

| Coating Aspect | Metallic Coating (Mylar) | No Metallic Coating (Latex) |

|---|---|---|

| Material | Aluminum | Not applicable |

| Function | Gas barrier, reflective quality | None (material itself is the barrier) |

| Permeability Impact | Significantly reduces helium diffusion | No direct impact on helium diffusion |

| Thickness | Very thin, atomic layer | Not applicable |

| Visual Effect | Shiny, reflective, opaque | Translucent or opaque (due to pigment) |

The metallic coating also gives mylar balloons their signature shiny appearance. It reflects light. This makes them stand out. But its primary function is protection. It helps keep the helium inside. This makes the balloon float longer. At AIHUA BALLOON, we ensure our mylar balloons have a high-quality metallic coating. We do this to maximize their float time. This is part of our commitment to producing reliable products. The metallic layer is essential for durability and performance. It is a key factor in why mylar balloons outperform latex.

Aside from material, what other factors make mylar balloons more durable than traditional helium balloons?

Have you ever wondered if there's more to mylar balloons' longevity than just their material? There definitely is.

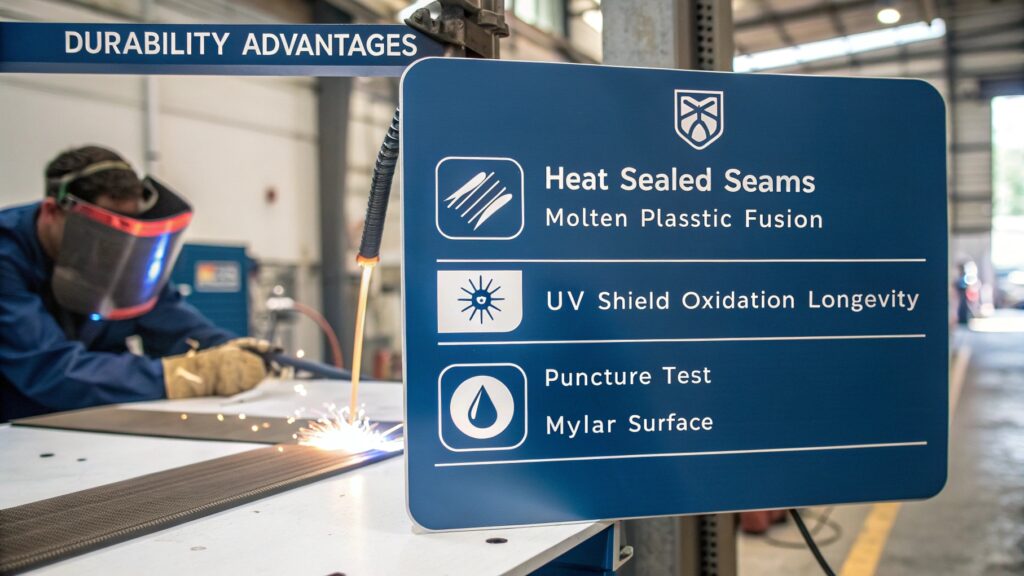

Beyond their superior material, mylar balloons are more durable than traditional latex balloons due to stronger heat-sealed seams15 that prevent leakage, their non-porous surface which makes them less prone to oxidation16, and a generally sturdier construction that resists punctures better.

From my perspective in manufacturing, durability depends on many things. It is not just the basic material. Mylar balloons benefit from several design and manufacturing choices that add to their strength.

First, consider the seams. Latex balloons are typically tied at the neck or have crimped ends. These areas can be weak points. They can leak. Mylar balloons, however, are made with heat-sealed seams. High heat is used to fuse the layers of mylar film together. This creates a very strong, airtight bond. These seams are much more secure than a hand-tied knot or a crimped seal. This means less chance for helium to escape from the edges.

Second, mylar's non-porous surface protects against oxidation. Latex is rubber. It reacts with oxygen in the air. This causes it to break down over time. It can become brittle. It then deflates faster. Mylar is a plastic film. It does not react with oxygen in the same way. This makes it more resistant to environmental degradation. It stays strong for longer.

Third, the overall construction of mylar balloons is generally sturdier. While latex balloons are very stretchy, they are also more delicate. They can pop easily if overinflated or if they touch a sharp object. Mylar balloons are less stretchy. But they are also more puncture-resistant than latex. This makes them more robust for handling and display.

Here is a breakdown of these additional durability factors17:

| Durability Factor | Latex Balloons | Mylar Balloons |

|---|---|---|

| Seam Type | Tied knots, crimped ends | Heat-sealed seams |

| Seam Strength | Prone to leaks | Very strong, airtight |

| Oxidation | Susceptible to breakdown from oxygen | Highly resistant to oxidation |

| Puncture Resistance | Lower (easily popped) | Higher (more robust against tears) |

| Environmental Resilience | More affected by UV, temperature | More stable in varied conditions |

At AIHUA BALLOON, we pay close attention to these manufacturing details. For our mylar balloons, we ensure our heat-sealing machines apply consistent pressure and temperature. This guarantees perf

ect seams. This is a critical step in achieving maximum float time. For latex, we focus on material quality and neck design to minimize inherent weaknesses. We provide quality products. This means understanding and optimizing all aspects of durability. The combination of superior material and manufacturing techniques makes mylar balloons winners in the durability contest.

Conclusion

The key reason mylar balloons outlast latex balloons is largely material. Mylar's non-porous structure and metallic coating trap helium, while latex's tiny pores let it leak out; stronger seams and better oxidation resistance also play a big part.

-

Discover the science behind Mylar balloons and why they outlast latex ones, ensuring your celebrations stay vibrant longer. ↩

-

Learn about the properties of helium balloons and why they deflate quickly compared to Mylar, enhancing your party planning. ↩

-

Explore this link to understand the properties of plastic film and its advantages in various applications, including balloon longevity. ↩

-

Understanding gas leakage in balloons can enhance your knowledge of balloon materials and their performance. ↩

-

Explore the latest trends and innovations in the balloon industry for better insights. ↩

-

Understand the role of microscopic pores in materials and their impact on gas retention. ↩

-

Understand the behavior of helium molecules and their interaction with various balloon materials. ↩

-

Explore the properties and applications of BoPET film in packaging and other industries. ↩

-

Learn about non-permeable barriers and their role in preventing gas escape in products. ↩

-

Discover the factors that influence how long balloons can float and stay inflated. ↩

-

Gain insights into gas permeability and its impact on material performance in various applications. ↩

-

Gain insights into material science and its critical role in product development and innovation. ↩

-

Explore the concept of diffusion and its relevance in gas movement through materials. ↩

-

Learn about the functional benefits of metallic coatings in enhancing balloon performance. ↩

-

Learn about the benefits of heat-sealed seams in enhancing product durability and performance. ↩

-

Understand the process of oxidation and its impact on the longevity of various materials. ↩

-

Understand the various factors that influence the durability and lifespan of balloons. ↩