How does UV resistance relate to latex balloon quality?

Worried your outdoor balloon displays1 will fade and pop under the sun? It's frustrating when decorations fail, ruining the look. The solution lies in understanding and choosing UV-resistant latex balloons2.

UV resistance is a direct measure of latex balloon quality3. High-quality balloons are made to withstand sunlight better. They keep their color and structure longer, reducing the risk of premature popping and ensuring your decorations look great from start to finish, especially for outdoor events.

As a procurement manager, you need reliable products that perform well in any condition. I have spent over a decade in this industry, and the impact of sunlight on balloons is a constant topic with clients. Let's explore why UV resistance is not just a feature, but a fundamental aspect of quality. Understanding this is the difference between sourcing for a successful event and a potential disappointment.

How does sunlight cause latex balloons to degrade?

Have you noticed balloons becoming weak and popping easily at outdoor events? This invisible process can ruin a display without warning. Sunlight's UV radiation is the main cause, relentlessly breaking down the latex itself.

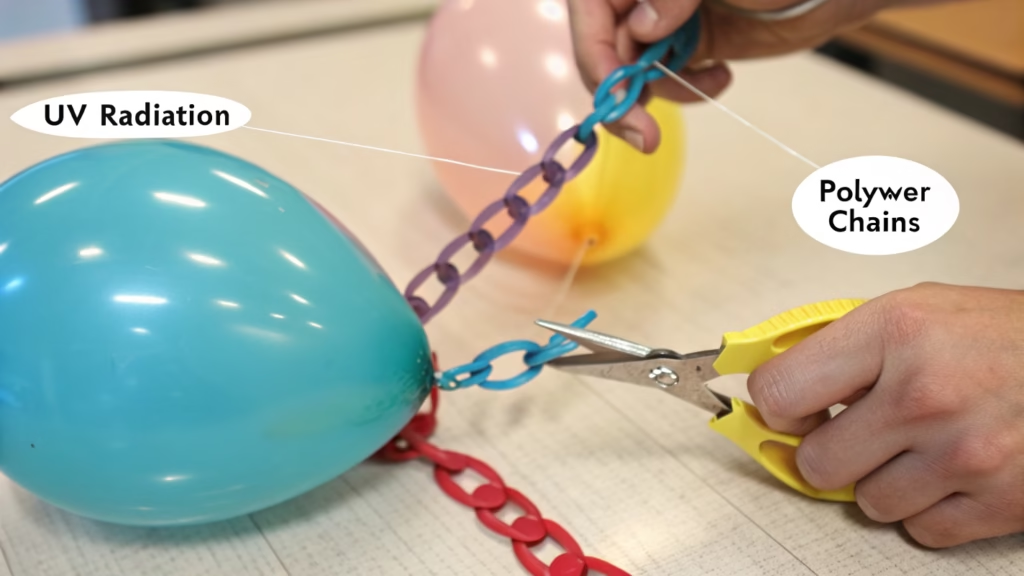

Sunlight's UV radiation triggers a process called photo-oxidation4. It chemically attacks and breaks down the long polymer chains that give latex its elasticity. This makes the balloon material brittle, fade in color, and become much more likely to pop with even small disturbances.

At AIHUA BALLOON, our R&D team focuses heavily on combating this. We call the process "photo-oxidation." The ultraviolet (UV) rays from the sun are high-energy. They act like tiny scissors, cutting the long, flexible polymer chains that make latex strong and stretchy. As these chains break, the balloon loses its structural integrity5 and becomes fragile. Think of it like a rubber band left out in the sun; it gets stiff and snaps easily. This same process happens to balloons. The longer a balloon is exposed to direct sunlight, the more these polymer chains are damaged. A high-quality balloon incorporates additives6 that help absorb or deflect this UV radiation, protecting the latex structure. Lower-quality balloons lack these protections and degrade much faster, sometimes within just a few hours. This degradation affects the balloon in two critical ways.

The Dual Impact of UV Degradation

| Impact Area | Description | Consequence for Your Display |

|---|---|---|

| Structural Damage | The breakdown of latex polymer chains weakens the balloon's wall, making it brittle and less flexible. | Higher risk of random popping, leading to a sparse or failed display. |

| Color Fading | UV radiation bleaches the pigments mixed into the latex, causing vibrant colors to appear dull and washed out. | The visual appeal is lost, making the decorations look old and tired. |

What are the visible differences between UV-resistant and standard balloons?

Are you trying to decide between two balloon options that look similar in the package? When exposed to sunlight, their true quality differences become very clear. It’s a costly discovery to make on an event day.

Visibly, after sun exposure, UV-resistant balloons maintain their vibrant color and glossy finish. Standard balloons will look chalky, faded, and opaque. You’ll also notice that standard balloons become visibly thinner in some areas and feel more brittle to the touch before they pop.

I remember a client who switched to a cheaper supplier for a large outdoor festival. The balloons looked fine indoors, but after just two hours in the sun, the brilliant red arch they built looked dusty and almost pink. Several balloons popped before the event even started. That is the real-world difference. High-quality, UV-resistant balloons are designed for better performance. The latex compound has a more uniform thickness, which helps distribute stress evenly. More importantly, we add specific antioxidants and UV inhibitors7 during the manufacturing process. These additives don't change the initial look but act as a powerful sunscreen for the balloon. In contrast, standard balloons lack these protective ingredients. When UV rays hit them, the oxidation process8 creates a chalky layer on the surface. This is the first sign of degradation. The color fades because the pigments are breaking down. This is why investing in truly UV-resistant products protects not just the balloon, but the professional image of the event.

Key Visual Indicators of Quality

- Color Retention: Premium balloons hold their true, deep color. Standard balloons will fade dramatically.

- Surface Finish: A superior balloon keeps its smooth finish. A degrading balloon develops a matte, dusty texture.

- Uniformity: UV-resistant balloons shrink evenly. Low-quality ones may develop weak, transparent spots before failing.

Can UV-resistant balloons last longer for outdoor events?

Are you tired of your balloon arrangements9 deflating or popping halfway through an outdoor party? You invest time and money, only for the sun to ruin your work. This is a common and expensive problem for event planners10.

Yes, absolutely. UV-resistant balloons are specifically engineered to last significantly longer outdoors. By resisting the damaging effects of sunlight, they maintain their structural integrity5 and color for days, not hours, making them the only reliable choice for multi-day events or long afternoons.

One of our biggest clients is a chain of resorts in a tropical location. They use balloons for poolside parties and beach weddings. They told me that before switching to our UV-resistant line, they had to replace their balloon displays1 every single day. Sometimes, decorations set up in the morning wouldn't even last until the afternoon reception. Now, their displays often last for two or three days, looking fresh the entire time. This dramatically cut their labor and material costs. The key is durability. Since UV radiation is the primary cause of balloon failure outdoors, countering it is the most effective way to extend a balloon's life. UV-resistant balloons are less prone to becoming brittle, so they can handle temperature changes and gentle breezes better than a standard balloon that has been weakened by the sun. This extended longevity means you can set up decorations well in advance without worrying about them failing before the guests arrive. It provides peace of mind and ensures a better return on your investment.

Factors Determining Outdoor Longevity

| Feature | Standard Balloon | UV-Resistant Balloon |

|---|---|---|

| Material Life | Begins to weaken and oxidize within 1-3 hours. | Maintains strength and flexibility for 12+ hours, often days. |

| Color Stability | Fading can be noticeable in as little as 2 hours. | Color remains vibrant for the entire duration of most events. |

| Pop Resistance | Becomes highly prone to popping as it gets brittle. | Stays elastic and is much less likely to pop from sun exposure. |

What manufacturing standards ensure a balloon is truly UV-resistant?

Do you find it hard to trust claims of "UV resistance" on packaging? Many brands make this claim, but their products fail in the sun. You need to know what to look for to ensure you get what you pay for.

True UV resistance is ensured through specific manufacturing processes and quality control, not just claims. Look for manufacturers with ISO 9001 certification11, which confirms consistent production quality. Also, inquire about their use of specific UV-inhibiting additives and rigorous testing protocols in their latex formula.

As a procurement manager, certifications are your best friend. At AIHUA BALLOON, our ISO 9001 certification isn't just a piece of paper; it's a commitment to a repeatable, high-quality process. For UV resistance, this starts with the raw materials. We source premium latex and mix it with a precise formula of antioxidants and UV absorbers. These aren't standard ingredients; they are specialty additives that increase production costs but are essential for performance. We then conduct our own stringent tests. We have a weathering chamber12 that simulates intense, prolonged sun exposure. We place our balloons alongside competitor products and measure the time it takes for them to fade and degrade. This data proves the effectiveness of our formula. A truly UV-resistant balloon is a result of intentional engineering. I always advise buyers like you to ask potential suppliers directly: "What specific additives do you use for UV protection, and can you provide test data to support your claims?" A reputable manufacturer will have this information ready.

What to Ask Your Supplier

- Certifications: "Are you ISO 9001 or Sedex certified?" These certifications point to a reliable and ethical manufacturing process.

- Material Composition: "What specific UV inhibitors7 or antioxidants are included in your latex compound?" Vague answers are a red flag.

- Testing Methods: "How do you test your balloons for UV resistance?" Look for evidence of controlled testing, not just anecdotal claims.

- Material Thickness: "What is the weight and average thickness of your balloons?" Thicker, more uniform balloons generally perform better.

Conclusion

Ultimately, UV resistance is not a luxury feature but a core indicator of a latex balloon's quality and reliability. It ensures your outdoor decorations remain vibrant and intact, protecting your investment and reputation.

-

Get insights on maintaining balloon displays outdoors to ensure they look great throughout the event. ↩ ↩

-

Explore the advantages of UV-resistant latex balloons to ensure your outdoor displays remain vibrant and intact. ↩

-

Discover the key factors that define high-quality latex balloons for your events. ↩

-

Understanding photo-oxidation can help you grasp how sunlight affects balloon quality and longevity. ↩

-

Learn how UV resistance maintains the structural integrity of balloons for better performance. ↩ ↩

-

Learn about the additives that enhance the quality and performance of latex balloons. ↩

-

Explore the role of UV inhibitors in enhancing the durability of latex balloons against sunlight. ↩ ↩

-

Understand the oxidation process and its effects on the lifespan of latex balloons. ↩

-

Get tips on creating balloon arrangements that withstand outdoor conditions and last longer. ↩

-

Discover how UV-resistant balloons can save event planners time and money by lasting longer. ↩

-

Learn about ISO 9001 certification and its importance in ensuring quality in balloon production. ↩

-

Find out how a weathering chamber is used to test the durability of balloons against UV exposure. ↩