How long do quality latex balloons last before inflating?

Struggling with balloon stock that might expire? Wasted inventory means lost profits and unhappy clients. Let's make sure your balloons are always ready for the party.

Quality latex balloons typically have a shelf life1 of about two years from their manufacture date for best performance. If you store them correctly in a cool, dark, and dry place, they can last even longer before becoming brittle and unusable.

That two-year guideline is a great starting point. But as a procurement manager2, you know the details are what truly matter. How you store them, who you buy from, and what to look for can make a huge difference in your inventory's performance and your bottom line. Let's break it down further. We will start with the most critical factor: storage.

What are the ideal storage conditions to maximize balloon shelf life?

Are your storage methods secretly ruining your balloons? Light and heat can quickly degrade your stock, leading to waste. Let's look at the simple steps to protect them.

Store latex balloons in a cool, dark, and dry place, away from direct sunlight and heat sources. The ideal temperature3 is between 10-20°C (50-68°F). Keep them in their original sealed packaging to protect them from oxygen and physical damage.

Based on my experience, proper storage is the single most important factor in preserving your balloon inventory4. I have seen perfectly good shipments ruined because they were left on a hot loading dock for just one afternoon. Latex is a natural product, and it is sensitive to its environment. You need to control three main things: temperature, light, and humidity5.

Temperature is Key

Heat makes latex soft and sticky. Cold makes it brittle. You need a stable, cool environment. We advise our partners to store balloons in a climate-controlled room, far away from heaters or vents. Consistency is just as important as the temperature itself.

Avoid Light Exposure

Sunlight is a balloon's worst enemy. The UV rays directly break down the chemical bonds in the latex. This makes the material weak and prone to popping. Even strong indoor lighting can have an effect over time. This is why we ship them in opaque bags.

Keep Them Dry and Sealed

Moisture can make balloons stick together, causing them to tear when you try to separate them. The original packaging also protects them from oxygen, which causes oxidation over time. Do not open the bags until you are ready to use the balloons.

| Factor | Ideal Condition | Why it Matters |

|---|---|---|

| Temperature | 10-20°C (50-68°F) | Prevents latex from becoming sticky or brittle. |

| Light | Total darkness | UV rays break down the chemical bonds in latex. |

| Packaging | Sealed Original Bags | Protects from oxygen, dust, and physical damage. |

Does shelf life vary between different latex balloon manufacturers?

Think all latex balloons are the same? Choosing a cheaper supplier can lead to brittle stock and high breakage rates. Let's explore why manufacturer quality6 is so important.

Yes, absolutely. High-quality manufacturers like AIHUA BALLOON use premium latex and advanced production processes. This results in a more durable balloon with a longer, more reliable shelf life compared to budget brands that may use lower-grade materials.

As someone who oversees production, I can tell you that not all balloons are created equal. The difference between a premium balloon and a low-quality one starts at the very beginning of the process. For a procurement manager like you, understanding these differences is vital for supply chain reliability.

The Role of Raw Materials

It all begins with the latex itself. We source high-grade liquid latex to ensure it has excellent purity and elasticity from the start. Some manufacturers may use lower-grade materials with more impurities. This can lead to a weaker final product that degrades much faster, even in perfect storage conditions7.

Consistency in Manufacturing

Our factory is ISO9001 certified. This means every stage of our production is standardized and monitored. From the dipping process to the curing temperatures, everything is controlled. This consistency ensures that a balloon made today has the same quality and lifespan as one made six months from now. A lack of process control at other factories leads to inconsistent quality, which is a major risk for bulk buyers.

Quality Control and Certification

Finally, a reputable manufacturer stands behind their product with rigorous testing and certifications like Sedex. We provide our partners with comprehensive quality reports. This gives you confidence that the product meets international safety standards and will perform as expected.

How can you identify expired or degraded balloons in bulk stock?

Worried about using bad balloons from your stock? One brittle balloon can pop mid-setup, causing delays and frustration. Here are the simple visual and physical cues to look for.

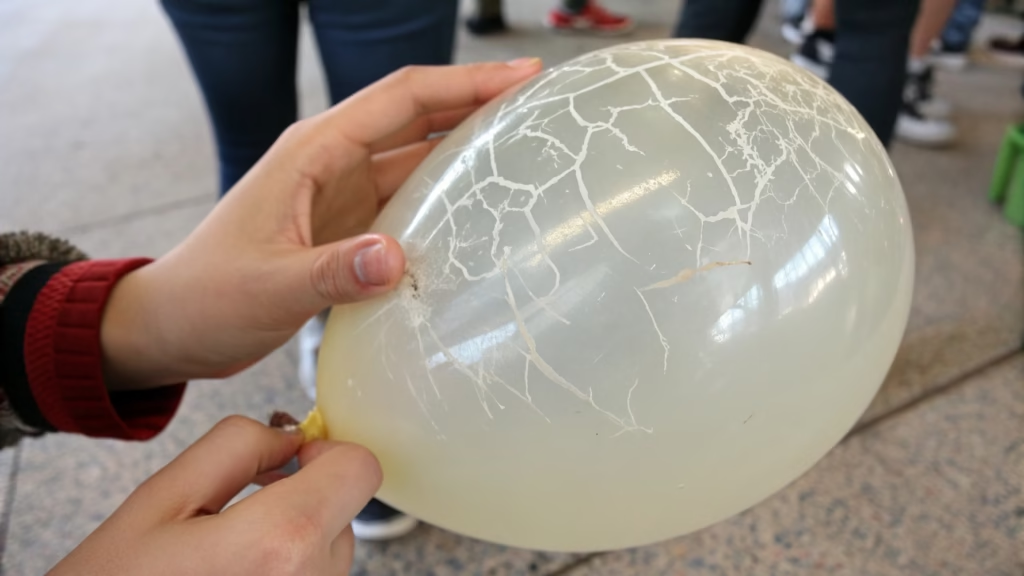

Check for physical signs. Degraded balloons often feel brittle or stiff, not soft and stretchy. They may have a chalky film, look faded, or feel sticky. When you try to inflate one, it might pop easily at low pressure.

You do not need a lab to check your inventory for degradation. A few simple spot checks can save you a lot of trouble. I recommend my clients establish a simple "first-in, first-out8" inventory system. And I also teach them to perform these quick tests on older stock before committing it to a large job.

Visual Cues

First, just look at the balloons. The colors should be vibrant and uniform. If they appear faded, discolored, or have splotches, that is a warning sign. You might also see a dusty or chalky film on the surface, which is a sign of latex oxidation.

The Feel Test

A fresh latex balloon is soft and pliable. Pick one up and gently stretch the neck. It should feel elastic. If it feels stiff, hard, or makes a slight cracking sound, the latex has become brittle. A sticky or oily texture is another red flag that the balloon has been exposed to heat.

The Inflation Test

The ultimate proof is in the inflation. Take a few balloons from the batch and try to inflate them. An old balloon might pop immediately or at a very small size. You may also see thin spots or "windows" appear in the surface as it inflates. This indicates the balloon wall is weak and unreliable.

| Check | Look For | Red Flag |

|---|---|---|

| Visual | Vibrant Color, Smooth Surface | Faded color, chalky film, blotches |

| Touch | Soft, Stretchy, Pliable | Brittle, stiff, sticky, or oily feel |

| Inflation | Inflates smoothly, holds shape | Pops easily, has thin spots, won't inflate |

Does custom printing affect the pre-inflation lifespan of latex balloons?

Does printing that logo compromise your balloon's lifespan? It's a valid concern for branded inventory. The good news is, with the right process, it doesn't have to.

When done correctly with high-quality, flexible inks9, custom printing10 has a negligible effect on the pre-inflation shelf life. The ink is designed to bond with the latex and stretch with it. Reputable suppliers ensure their printing process11 does not degrade the balloon.

This is a question I get often, especially from large retail partners who rely on branded products. It is a very important point, because a poor printing job can definitely damage a balloon. The quality of the final product depends entirely on the ink and the process used by the manufacturer.

The Importance of Ink

We use specially formulated, flexible screen-printing inks. These inks are designed to cure on the latex surface without making it rigid. They form a strong bond but also stretch with the balloon as it inflates. A cheap, low-quality ink will create a stiff patch that can cause the balloon to tear or pop from that spot.

The Printing and Curing Process

Our printing process is carefully controlled. After the ink is applied, the balloons go through a curing stage. We use a specific temperature and duration to ensure the ink dries completely without applying excessive heat, which could harm the latex. Some printers might rush this process or use high heat, which compromises the balloon's structural integrity before it even gets to your warehouse.

Choosing a Printing Partner

This is why I always recommend working with a manufacturer that handles both balloon production and printing in-house. We control every variable. We ensure that our printed balloons have the same reliability and shelf life as our unprinted ones. When you source from a company that outsources its printing, you lose that quality assurance.

Conclusion

The two-year shelf life is a guideline. Proper storage, choosing a quality manufacturer, and regular stock checks are key to ensuring your latex balloons perform perfectly when you need them.

-

Understanding the shelf life helps you manage inventory effectively and avoid waste. ↩

-

Gain insights into the role and responsibilities of a procurement manager. ↩

-

Temperature control is crucial for maintaining balloon quality and preventing waste. ↩

-

Effective inventory management ensures you always have quality balloons ready. ↩

-

Understanding humidity's impact can help you store balloons more effectively. ↩

-

Choosing the right manufacturer ensures better quality and reliability. ↩

-

Proper storage conditions can significantly extend the life of your balloons. ↩

-

Implementing this system can help you manage balloon stock effectively. ↩

-

Discover how flexible inks can maintain balloon integrity during inflation. ↩

-

Understand the impact of printing on balloon quality and longevity. ↩

-

Learn about the importance of a controlled printing process for quality. ↩