Latex vs Mylar Balloons: How do manufacturing processes differ?

Choosing the right balloon is crucial for your business. The differences in latex and Mylar manufacturing directly impact your inventory, quality, and profits. Let's break down the process.

Latex balloons are made by dipping molds into liquid latex from rubber trees. Mylar balloons are produced by heat-sealing two sheets of metallized plastic film together. This fundamental difference in production creates distinct properties for each balloon, impacting everything from cost to performance.

Now that you have the basic idea, you can see that these are two very different products. For a procurement professional, understanding these differences is key to making the best purchasing decisions for your company. Let's dive deeper into the specifics that matter most, starting with the raw materials themselves.

What raw materials are used for each balloon type?

Unsure about the materials in your sourced balloons? This uncertainty can risk compliance and customer safety. I’ll clarify the exact raw materials for both latex and Mylar balloons.

Latex balloons come from natural rubber tree sap1, a biodegradable material2. Mylar balloons, or foil balloons, are made from a synthetic plastic film3 like nylon. This plastic is then coated with a thin layer of aluminum, giving it its metallic look.

In my 37 years in this industry, I've seen how much the source material matters for final product quality. The journey from raw material to finished balloon is completely different for latex and Mylar, and it all starts at the source. Understanding this is the first step to mastering your procurement strategy.

The Natural Origin of Latex

Latex begins its life as a milky sap tapped from rubber trees. This natural origin is a huge selling point, as it makes the final product biodegradable. The sap is collected, and then liquid latex is compounded with pigments for color and other agents to ensure elasticity and durability4. This connection to a natural, renewable resource is a major factor for businesses focused on sustainability5.

The Synthetic Makeup of Mylar

Mylar, on the other hand, is a synthetic product. It's technically a brand name for a type of stretched polyethylene terephthalate (PET) film. The base material is a kind of plastic, which is then laminated with a layer of metallic coating, usually aluminum. This multi-layered structure is what gives it its classic foil look and non-porous nature. The process is much more industrial and relies on petroleum-based products6.

| Feature | Latex Balloons | Mylar (Foil) Balloons |

|---|---|---|

| Source Material | Natural rubber tree sap | Synthetic plastic film (Nylon/PET) |

| Coating | None (pigment mixed in) | Laminated with aluminum |

| Sustainability | Biodegradable, from a renewable resource | Not biodegradable, petroleum-based |

How does the production process impact wholesale costs?

Struggling to balance your budget with quality demands? The manufacturing process is the main reason for the price difference between balloon types. I'll explain how it affects your costs.

Latex balloon production is highly automated and involves dipping molds, which is cost-effective7 for high volumes. Mylar production is a multi-step process8 involving printing, metallizing, cutting, and heat-sealing. This complexity makes Mylar balloons more expensive to produce per unit.

As someone who oversees production, I see the cost implications every single day. The efficiency of the latex dipping line versus the precision needed for sealing Mylar shapes creates a clear price gap. Let’s break down the steps to see exactly where these costs come from and why you pay what you pay.

The Efficiency of Latex Production

The process for making latex balloons is built for speed and volume. It involves dipping hundreds of balloon-shaped forms, called mandrels, into a large vat of liquid latex. After dipping, they are passed through ovens to vulcanize, or cure, the rubber. The finished balloons are then stripped from the forms. This continuous, large-scale process significantly lowers the cost per balloon, making them the go-to choice for bulk orders. The main cost drivers9 are raw latex prices and energy for the curing ovens.

The Multi-Step Mylar Process

Mylar balloon production is more intricate. It starts with large rolls of nylon or PET film. These sheets are first printed with the desired design, sometimes before the metallic layer is even applied. After printing and metallizing, two sheets are placed together, and a machine heat-seals the edges in the desired shape, leaving a small valve opening for inflation10. The complexity of printing, aligning the sheets, and precision sealing makes the process slower and more costly. Custom shapes require custom sealing dies, which adds to the expense.

Which material allows for better durability and helium retention?

Worried about balloons deflating too quickly? Your customers’ satisfaction depends on how long the celebration lasts. I will explain which material holds up better over time.

Mylar balloons offer superior durability and helium retention11. The non-porous, metallized plastic film prevents helium molecules from escaping easily, allowing them to stay afloat for weeks. Latex is naturally porous, so helium slowly seeps out, causing deflation within 12-24 hours.

We've conducted countless tests on float times12 in our labs. The results are always consistent. While latex is perfect for short-term events, Mylar is the undisputed champion for long-lasting displays. This performance difference is a direct result of the material's physical structure that we discussed earlier.

Why Mylar Lasts Longer

The key is in the material's structure. Mylar is a laminated sheet of plastic and metal. This structure is not porous. The tiny helium atoms can't easily pass through it. As a result, Mylar balloons can often stay fully inflated and floating for a week or even longer. They are also tougher and less likely to pop from incidental contact, though they are vulnerable to sharp objects. This durability makes them ideal for longer events or as gifts.

The Porous Nature of Latex

Latex, despite its strength and elasticity, is a natural material with microscopic pores. Helium atoms are among the smallest gas atoms, so they are able to slowly escape through these pores. This is why a standard helium-filled latex balloon will typically float for less than a day. While treatments like HI-FLOAT can coat the inside to extend float time, the material's inherent porosity remains its biggest limitation for helium retention.

| Factor | Latex Balloons | Mylar (Foil) Balloons |

|---|---|---|

| Helium Retention | Poor (8-12 hours) | Excellent (1-2+ weeks) |

| Material Structure | Naturally porous | Non-porous film |

| Durability | Flexible but can pop | Puncture-resistant but can tear |

| Best Use Case | Short-term events, large quantities | Long-lasting displays, gifts |

What are the limitations for custom printing on each material?

Need complex, high-resolution graphics on your balloons? The material you choose will directly limit your design options. Let's look at the printing capabilities13 of each type.

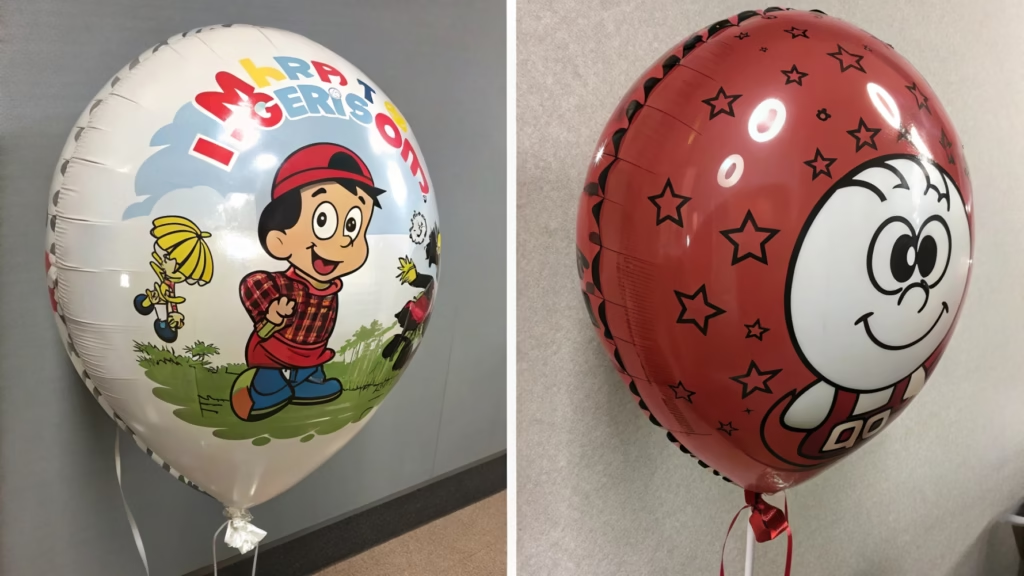

Mylar balloons are far superior for custom printing14. Their flat, non-porous surface allows for high-resolution, full-color photorealistic images. Latex balloons stretch when inflated, which distorts the image. Printing on latex is typically limited to simpler logos and text.

We work with clients on custom designs all the time, and the conversation always starts with managing expectations based on the material. You can't achieve the same result on both types. Thinking about the printing process explains why. Mylar is printed flat, like a piece of paper, while latex is printed on a soft, curved, and ultimately stretched surface.

High-Fidelity Printing on Mylar

The major advantage of Mylar for customization is that it's printed while the material is still a flat sheet. This allows for very precise printing methods, like rotogravure or digital printing, to be used. You can achieve crisp, detailed, multi-color designs that cover the entire surface of the balloon from edge to edge. This makes Mylar the only choice for complex logos, character balloons, and even printing photographs. The metallic surface can also be used to create stunning visual effects.

Simplicity in Latex Printing

Printing on latex balloons is more challenging. The printing happens while the balloon is slightly inflated to create a firm surface, but the final design will be distorted once the balloon is fully inflated. Because of this stretching, designs must be kept simple. Typically, this involves one or two-color logos or text using a screen-printing process called silk-screening. The ink also needs to be flexible15 enough to stretch with the balloon without cracking. Complex, full-bleed images are simply not possible.

Conclusion

Understanding these manufacturing differences is key. Latex is a cost-effective, natural choice for bulk, while Mylar offers superior durability, float time, and high-resolution printing for premium applications.

-

Learn about the sustainable sourcing of natural rubber tree sap and its applications in various industries. ↩

-

Find out how biodegradable materials contribute to sustainability and reduce environmental impact. ↩

-

Understand the production process and applications of synthetic plastic film in modern manufacturing. ↩

-

Learn about the factors that influence balloon durability and how to choose the right type for your needs. ↩

-

Learn about the environmental implications of balloon production and how to make sustainable choices. ↩

-

Learn about the environmental concerns associated with petroleum-based products and alternatives. ↩

-

Discover tips for selecting budget-friendly balloons without compromising on quality. ↩

-

Understand the significance of multi-step processes in manufacturing and their impact on product quality. ↩

-

Get insights into the factors that influence balloon manufacturing costs and pricing. ↩

-

Explore effective methods for inflating balloons to ensure they look their best at events. ↩

-

Explore the science behind helium retention in balloons and its impact on event planning. ↩

-

Find out how long different types of balloons float and what affects their longevity. ↩

-

Explore the differences in printing capabilities between latex and Mylar balloons for your designs. ↩

-

Get insights into effective techniques for achieving high-quality custom prints on balloons. ↩

-

Understand the importance of flexibility in materials and its applications in various products. ↩