Latex vs Mylar Balloons: What are the potential risks of stocking each type?

Worried about the hidden risks in your balloon inventory? A single safety issue or environmental complaint can damage your brand. I'll help you understand the risks of each type.

Stocking latex balloons brings risks of choking for young children and potential allergic reactions1. Mylar balloons, on the other hand, can cause power outages if they hit electrical lines and create long-lasting plastic pollution. Each type requires a different risk management strategy for your business.

I've spent over a decade in the balloon industry, and I've seen firsthand how these risks can play out for large retailers. The details matter, not just for safety, but for your supply chain, storage, and even your shipping costs. Let's break down these factors one by one, so you can stock your shelves with confidence. It all starts with how long they last in your warehouse.

Which type has a longer shelf life and requires specific storage conditions?

Losing balloon stock to premature aging is a costly problem. This waste directly cuts into your profit margins. I'll explain the specific storage needs for each balloon type.

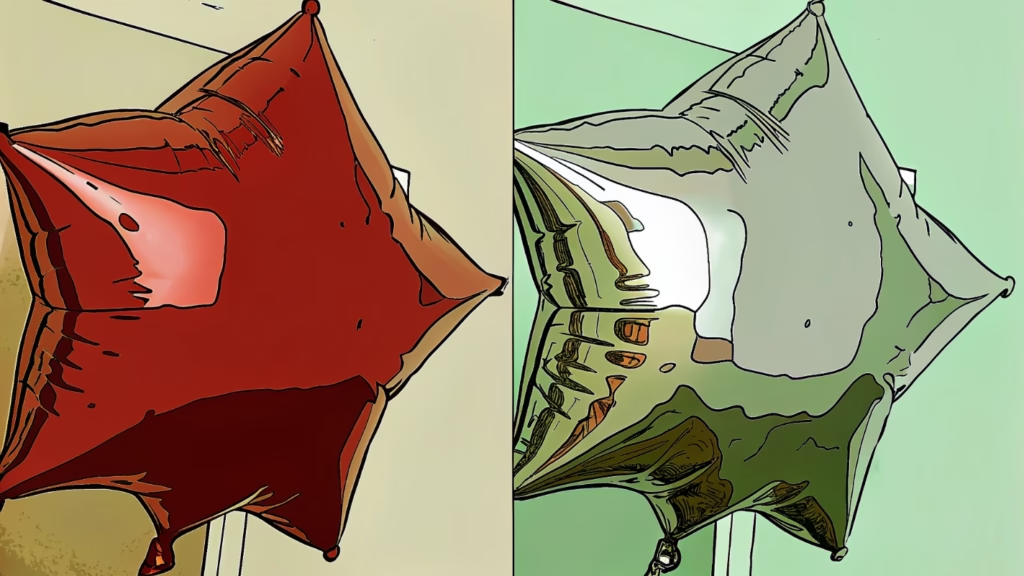

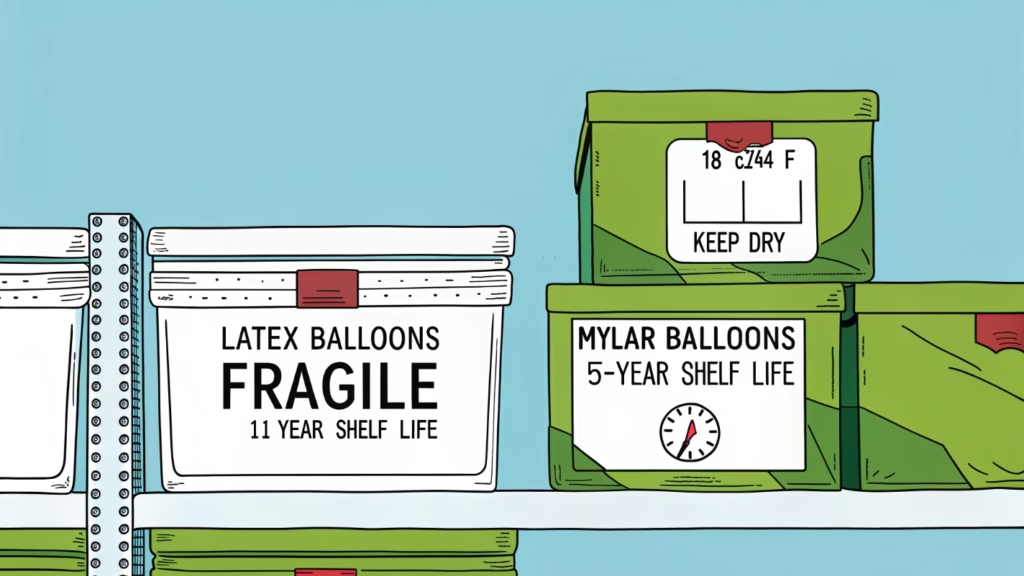

Mylar balloons have a much longer shelf life, lasting for years if stored properly. Latex balloons are more sensitive; they degrade with exposure to heat, light, and oxygen, and typically have a shelf life of about one year. Proper storage is crucial for latex.

From my experience, shelf life is a critical factor for procurement managers2 like you. Mylar balloons are very forgiving. They are made from a stable nylon material that isn't porous, so they don't lose integrity over time. You can store them for several years without much worry, as long as they are kept dry and away from sharp objects.

Latex balloons are different. They are made from natural rubber, which means they are sensitive to the environment. Exposure to UV light, heat, or even the oxygen in the air will cause them to oxidize and become brittle. I've visited warehouses where entire shipments of latex balloons were ruined because they were stored near a window or a heat source. To protect your investment, you must store latex balloons in a cool, dark place.

Here is a quick comparison:

| Factor | Latex Balloons | Mylar Balloons |

|---|---|---|

| Shelf Life | ~1 year | 3-5+ years |

| Key Risk | Oxidation, becoming brittle | Punctures, physical damage |

| Storage | Cool, dark, dry place | Dry, away from sharp items |

How do shipping costs and durability compare when importing in bulk?

Worried that shipping costs are eating into your balloon profit margins? Damaged goods arriving at your warehouse can erase any savings you made on the initial purchase. I'll show you how to manage both.

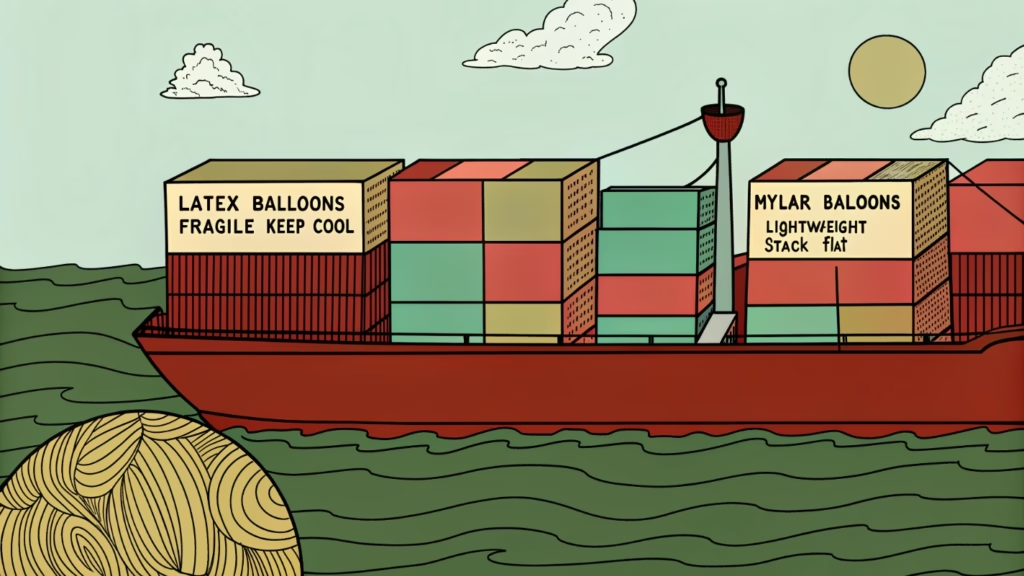

Mylar balloons are generally lighter but can be bulkier, making shipping costs variable. They are very durable against punctures. Latex balloons are heavier and more compact, but their packaging must protect them from pressure and heat to prevent damage during transit.

When you're importing thousands of units, every detail about shipping matters. Let's look at weight and volume. Latex balloons are dense and can be packed very tightly. This means you can fit a lot of units into a single carton, which can be efficient. However, the overall weight adds up quickly, which is a key factor in shipping costs. Mylar balloons are incredibly light, but they often come in larger, flatter packaging that can take up more space. You have to balance weight versus volume to find the most cost-effective solution.

Durability during shipping is another big concern. Mylar is tough. Its nylon material resists punctures well. Latex, however, is more delicate. If a carton is crushed or exposed to extreme heat in a container, the latex can fuse together or become brittle. At AIHUA BALLOON, we've invested heavily in quality packaging to prevent this. We use reinforced cartons and sometimes climate-controlled shipping to ensure the balloons arrive in perfect condition. It’s a step I always recommend our partners consider.

What are the compliance risks regarding material safety and biodegradability?

Are you concerned about meeting complex safety and environmental regulations3? Failing a compliance audit can lead to fines and force you to pull products from your shelves. I'll clarify the rules for you.

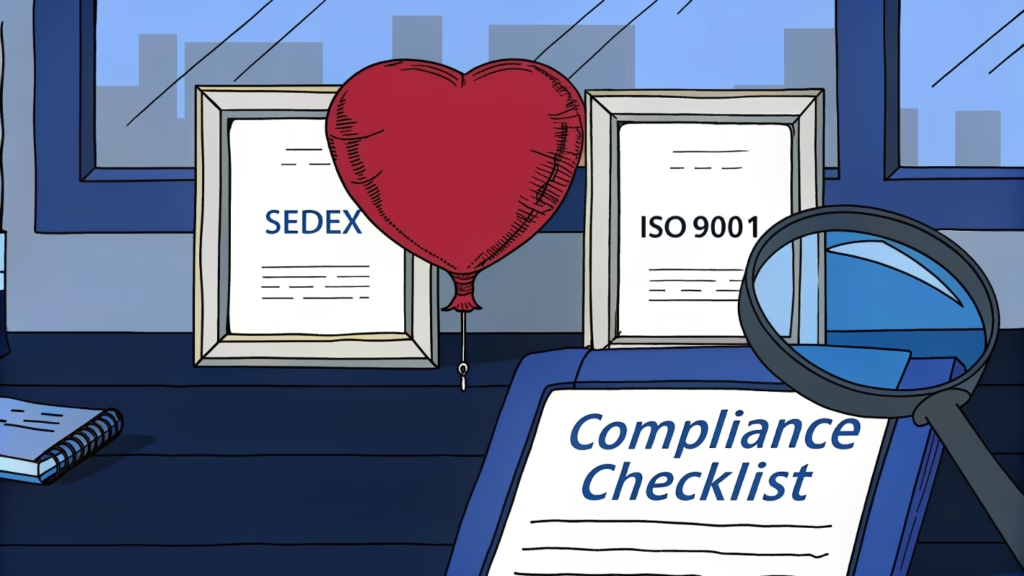

The main compliance risk for latex is the potential for allergic reactions1, requiring clear labeling. For Mylar, the risk is its non-biodegradable nature, which faces growing scrutiny from environmental regulations in many regions. Both must meet general child safety standards.

Navigating compliance is one of the biggest challenges for retailers. The rules are different for each material. For latex balloons, the primary safety concern is allergies. Natural rubber latex can cause reactions in some people. In many countries, regulations require clear warning labels on packaging. The other major issue is the choking hazard4 for children under eight, which also requires specific warnings.

Mylar balloons face a different set of challenges. Their biggest compliance risk is environmental. Since they are made of plastic and metal, they do not biodegrade. Many cities and even some countries are introducing laws to restrict or ban single-use plastics, and Mylar balloons are often included in these discussions. As a procurement manager, you need to stay ahead of these trends. The metallic coating also presents an electrical hazard risk, and some areas have rules about using weights on Mylar balloons to prevent them from floating into power lines. At AIHUA, we are Sedex and ISO9001 certified, ensuring our products and processes meet the highest global standards for safety and ethics.

How does the risk of defects and air leakage differ between the two materials?

Do you worry about customer complaints from balloons that deflate too quickly? Defective products not only lead to returns but also damage your customers' trust in your brand. I can help you minimize this.

Latex balloons are naturally porous and will slowly lose air over a day or two. Mylar balloons are non-porous, so they should hold air for weeks; any leakage is typically a manufacturing seam defect. Quality control is key to minimizing defects in both types.

Defects and leakage are a constant concern in the balloon business. It's important to understand that the two materials behave very differently. Latex is a natural material with microscopic pores. This means that even a perfect latex balloon will gradually lose helium or air over 12-24 hours. This is not a defect; it's just the nature of the material. A true defect in latex would be a pinhole or a weak spot that causes it to pop easily.

Mylar balloons, on the other hand, are designed for longevity. The nylon material is non-porous, so a well-made Mylar balloon can stay inflated for weeks. If a Mylar balloon leaks, it is almost always a manufacturing defect, usually in the heat-sealed seam or the self-sealing valve. As a manufacturer, this is where we focus our quality control5. I personally oversee our production lines where we conduct inflation tests and rigorous seam inspections to catch these issues before they ever leave our factory. Partnering with a supplier who takes quality control this seriously is your best defense against customer complaints.

Conclusion

Choosing between latex and Mylar involves weighing different risks. Latex has allergy and choking hazards, while Mylar has electrical and environmental risks. Understanding these helps you stock smarter and safer.

-

Understand how to manage allergic reactions to latex balloons with proper labeling and safety measures. ↩ ↩

-

Gain insights tailored for procurement managers to make informed decisions about balloon inventory. ↩

-

Stay updated on environmental regulations that could impact your balloon business and compliance. ↩

-

Learn about choking hazards to ensure safety and compliance in your balloon inventory. ↩

-

Discover best practices for quality control to minimize defects and ensure product reliability. ↩